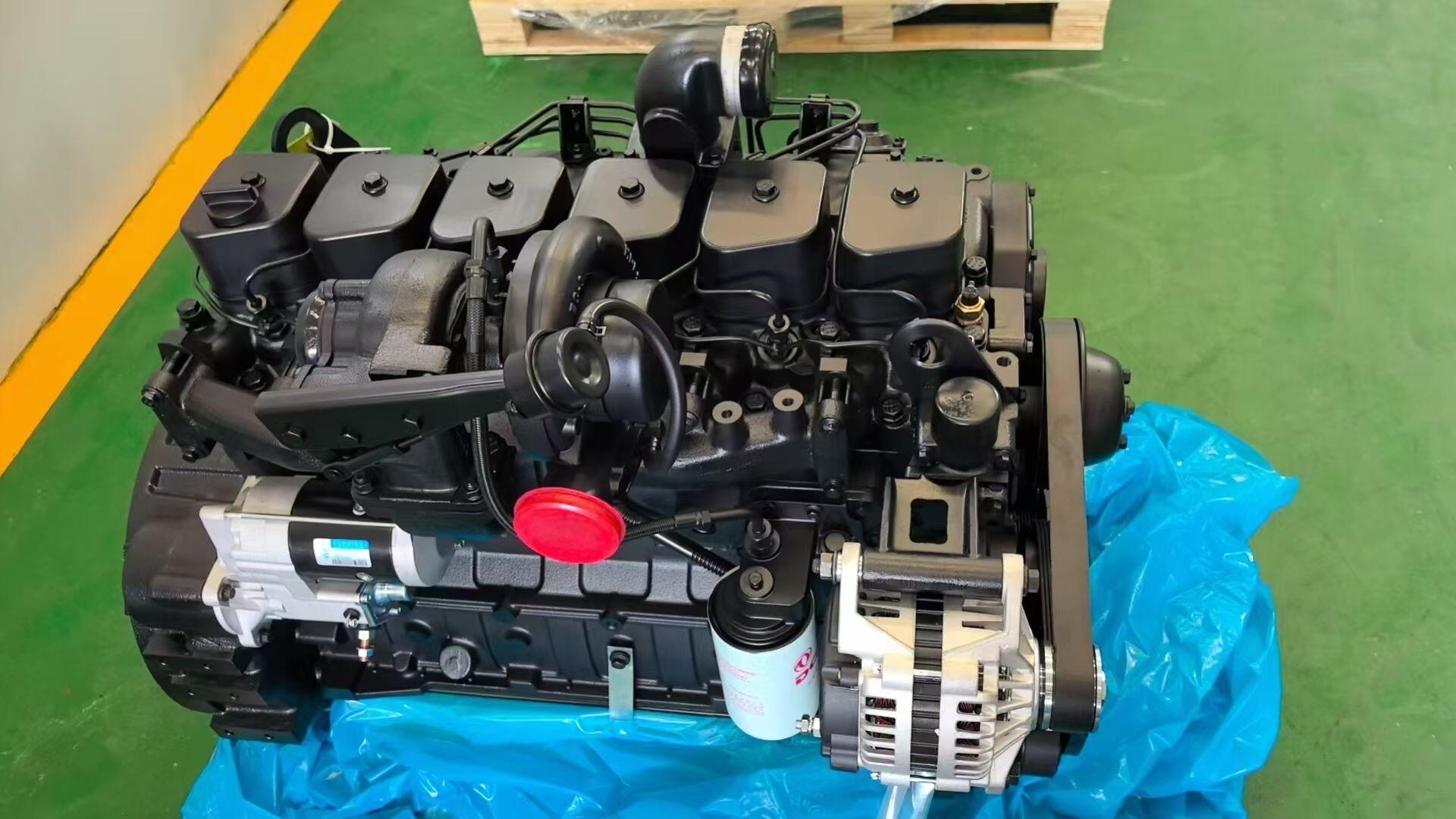

Motorët Cummins kanë fituar reputacionin e tyre si disa nga termocentralet më të besueshme dhe më të qëndrueshme në aplikimet komerciale dhe industriale në mbarë botën. Megjithatë, si çdo sistem mekanik kompleks, këta motorë të fuqishëm mund të përjetojnë probleme të ndryshme gjatë jetëgjatësisë së tyre operative. Të kuptuarit e problemeve të zakonshme dhe zgjidhjeve të tyre mund të ndihmojë menaxherët e flotës, mekanikët dhe operatorët të ruajnë performancën optimale duke minimizuar kohën e kushtueshme të ndërprerjes. Pavarësisht nëse keni të bëni me ndërlikime të sistemit të karburantit, probleme me ftohjen ose keqfunksionime elektrike, diagnoza e duhur dhe ndërhyrja në kohë janë thelbësore për ruajtjen e jetëgjatësisë së motorit tuaj. motor Cummins .

Probleme të Lidhura me Sistemin e Karburantit

Probleme të Injektorëve të Karburantit

Dështimet e injektorëve të karburantit përfaqësojnë njërën nga problemet më të shpeshta që hasen me motorët Cummins nëpër vitet e ndryshme modeli dhe aplikime. Këto pjesë të saktësisë janë përgjegjëse për dërgimin e sasisë saktë të karburantit në secilin cilindër në momentin e duhur. Kur injektorët bllokohen, konsumohen ose dëmtohen, motori mund të tregojë simptoma si xhelimi i parregullt, zvogëlimi i fuqisë, konsumi i rritur i karburantit dhe tymi i tepërt i zi nga dalja. Sistemi i karburantit me presion të lartë në motorët modernë Cummins funksionon në presione mbi 30,000 PSI, gjë që i bën këto pjesë veçanërisht të prekshme ndaj ndotjes nga karburant i cilitetë dobët ose sisteme filtrimi të papërshtatshme.

Mirëmbajtja e rregullt e injektorëve të karburantit përfshin përdorimin e aditiveve të cilësisë së lartë për dijelin që janë projektuar për të pastruar depozitat e karbonit dhe për të parandaluar bllokimin e injektorëve. Shërbimet profesionale të pastrimit mund të rikthejnë performancën e injektorit nëse vërehen në kohë, por injektorët e dëmtuar shumë zakonisht duhet të zëvendësohen. Masat parandaluese përfshijnë zëvendësimin e filtra të karburantit sipas specifikimeve të prodhuesit, përdorimin e burimeve të miratuara të karburantit dhe zbatimin e praktikave të duhura të ruajtjes së karburantit për të parandaluar ndotjen me ujë dhe rritjen mikrobike.

Përmbajtje e Filtër të Karburantit

Filtrat e ndotur të karburantit mund të komprometojnë shpejt performancën dhe besnikërinë e çdo sistemi motorik Cummins. Motorët modernë me dizel kërkojnë karburant jashtëzakonisht të pastër për të funksionuar në mënyrë efikase, dhe filtra të ndotur mund të çojnë në mungesë karburanti, zvogëlim të fuqisë së motorit dhe dëmtime potenciale të pjesëve të shtrenjta të sistemit të karburantit. Ndërsa ndotësit e zakonshëm përfshijnë ujin, pluhurin, grimcat e kaltërsisë dhe rritjen biologjike që mund të ndodhin në rezervuarët e karburantit në kushte të caktuara. Ndotja me ujë është veçanërisht problematike pasi mund të shkaktojë korrozion në pjesët e sistemit të karburantit dhe të ofrojë një mjedis ku bakteriet dhe shtëllinjat mund të zhvillohen.

Zgjidhja përfshin zbatimin e një strategjie të plotë filtrimi të karburantit që përfshin filtra primarë dhe sekondarë, ndarës uji dhe monitorim të rregullt të cilësisë së karburantit. Operatorët duhet të vendosin një skemë rutine kontrolli për filtra karburanti dhe t'i zëvendësojnë ato sipas rekomandimeve të prodhuesit, në vend se të presin të paraqiten probleme performace. Instalimi i sistemeve të monitorimit të cilësisë së karburantit mund të ofrojë paralajmërime të hershme për problemet e ndotjes para se këto të ndikojnë në funksionimin e motorrit.

Komplikime të Sistemit të Ftohjes

Probleme me Ngrohjen e Tepruar

Ngarkesa e motorit mbetet një shqetësim kritik për operatorët e motorrave Cummins, pasi temperaturat e larta mund të shkaktojnë dëmtime të rënda brendshme, përfshirë kokë cilindërash të deformuara, paketa kapakullash të shpërthyer dhe blloqe motori të crackuara. Ngarkesa zakonisht rezulton nga dështimet e sistemit të ftohjes, si bllokime të radiatorit, mospunime të termostatit, dështime të pompës së ujit ose nivele të pamjaftueshme të agjentit të ftohjes. Faktorë të jashtëm si temperatura ambientale ekstreme, kushte ngarkese të rënda dhe ajër i dobët qarkullues nëpër radiator mund të përshkallëzojnë stresin e sistemit të ftohjes dhe të çojnë tek problemet e lidhura me temperaturën.

Parandalimi i nxehtësirës së tepërt kërkon kontroll të rregullt të të gjitha pjesëve të sistemit të ftohjes, përfshirë gypat, kliptet, lamelat e radiatorit dhe nivelin e likidit të ftohjes. Sistemi i ftohjes duhet të testohet me presion çdo vit për të identifikuar rrjedhjet potenciale para se të bëhen problematike. Çfarësia e likidit të ftohjes është po aq e rëndësishme, pasi likidi i degraduar ose i ndotur humb aftësinë për të transferuar nxehtësinë në mënyrë efikase dhe mund të shkaktojë korrozion brenda kanaleve të sistemit të ftohjes.

Rrjedhje dhe Humbje Likidi Ftohjeje

Përthithjet e agjentit ftohës përfaqësojnë një sfidë të zakonshme mirëmbajtjeje që mund të eskalojë shpejt në dëmtime të mëdha të motorrit nëse nuk merren parasysh menjëherë. Këto përthithje mund të ndodhin në pika të ndryshme përgjatë sistemit të ftohjes, duke përfshirë lidhjet e gypave, sipërfaqet e paketatave, bërthamat e radiatorit dhe kalimet e brendshme brenda bllokut të motorrit ose kokës së cilindrit. Përthithjet e jashtme zakonisht janë më të lehta për t'u identifikuar me anë të kontrollit vizual, ndërsa ato të brendshme mund të dalin në pah vetëm përmes simptomave si dimë i bardhë nga mbarësia, harxhim i agjentit ftohës pa përthithje të dukshme të jashtme, ose ndotja e vajit të motorrit.

Zgjidhja e rrjedhjeve të lëngut të ftohjes kërkon një kontroll sistematik të tërë sistemit të ftohjes për të identifikuar të gjitha pikat e mundshme të dështimit. Zëvendësimi i rregullt i tubave, klemave dhe paketimeve sipas skedarit të prodhuesit mund të parandalojë shumë probleme që lidhen me rrjedhjet. Kur supozohen rrjedhje të brendshme, mund të jetë e nevojshme një test diagnostik profesionist që përfshin testimin e shtypjes dhe analizën kimike për të përcaktuar shkallën e problemit dhe për të zhvilluar një strategji riparimi të përshtatshme.

Dëmtime të Sistemit Elektrik

Probleme me Alternatorin dhe Ngarkimin

Problemet e sistemit elektrik mund të ndikojnë në mënyrë të konsiderueshme në funksionimin dhe besnikërinë e instalimeve moderne të motorrave cummins. Alternatori shërben si burimi kryesor i energjisë elektrike kur motorri është në punë, duke ruajtur ngarkesën e baterisë dhe furnizuar me energji të ndryshme sisteme elektrike përfshirë kompjuterat e injeksionit të karburantit, sensorët dhe pajisjet ndihmëse. Dështimet e alternatorit mund të shfaqen si paralajmërime për çngarkimin e baterisë, dritë të zbutura, mungesë funksionimi të sistemeve elektrike, ose humbje totale të energjisë elektrike. Këto probleme shpesh zhvillohen ngadalë, gjë që bën zbulimin e hershëm të tyre të thelbësishëm për parandalimin e dështimeve të papritura.

Testimi i rregullt i tensionit të sistemit të ngarkimit dhe dalja e rrymës mund të zbulojë probleme të ndërtuara në alternator para se të rezultojnë në dështim të plotë. Inspektimi vizual i montimit të alternatorit, tensionit të rripit dhe lidhjeve elektrike duhet të kryhet gjatë intervaleve rutinë të mirëmbajtjes. Gjendja e baterisë luhan edhe një rol të rëndësishëm në performancën e sistemit të ngarkimit, pasi bateritë e dobëta ose të dëmtuara mund të ushtrojnë shtresë të tepërt mbi alternatorin dhe të çojnë në dështim të parakohshëm.

Dështimet e Sensorëve dhe Kodi i Gabimeve

Sistemet moderne të motorrave Cummins përfshijnë numra të madhë elektronikë sensorë që monitorojnë parametra të ndryshëm të motorrit dhe ofrojnë përshtatje në modulin e kontrollit të motorrit. Këta sensorë matin vlera kritike si temperatura e likidit të ftohjes, presioni i vajit, presioni i karburantit, temperatura e gazeve të shkarkimit dhe presioni i bllokimtisë së turbokompresorit. Kur sensorët dështojnë ose japin lexime të pasakta, sistemi i kontrollit të motorrit mund të nxjerrë kode të gabimeve, të zvogëlojë fuqinë e motorrit, ose të nisë sekuencat mbrojtëse të fikjes për të parandaluar dëmtimin e motorrit.

Procedurat diagnostikore për problemet e lidhura me sensorët zakonisht përfshijnë përdorimin e mjeteve elektronike diagnostikuese për të lexuar kodet e gabimeve dhe për të monitoruar të dhënat reale të sensorëve. Diagnoza e saktë kërkon njohjen e funksionit specifik të sensorit dhe marrëdhënien e tij me funksionimin e përgjithshëm të motorrit. Pasterimi i rregullt dhe inspektimi i lidhjeve të sensorëve mund të parandalonë shumë mënyra dështimi, ndërsa zëvendësimi me sensorë origjinale ose të barabartë siguron kalibrimin dhe besueshmërinë e duhur.

Probleme të Lidhura me Turbokompresorin

Probleme me Shtypjen e Furrës

Problemet me turbinkarin kanë ndikim të konsiderueshëm në karakteristikat e performancës së konfigurimeve të motorrave Cummins me furër. Këto pajisje të sakta bazohen në energjinë e gazrave të shkarkimit për të ngjeshur ajrin hyrës, duke rritur dendësinë e fuqisë dhe efikasitetin e motorrit. Problemet e zakonshme të turbinkarit përfshijnë humbjen e shtypjes së furrës, konsum të tepërt të vajit, çmendje bejngjesh dhe dëmtim të turbinës ose të ventilatorit të kompresorit. Sintomat mund të përfshijnë zvogëlim të fuqisë së motorrit, tym blu ose të zi nga sistemi i shkarkimit, zhurma të pazakontë nga zona e turbinkarit dhe rritje të shkallës së konsumit të vajit.

Parandalimi i problemeve të turbokarikuesit kërkon zbatimin e procedurave të duhura të funksionimit, përfshirë periudha të mjaftueshme ngrohjeje dhe ftohjeje, ndryshime të rregullta të vajit me lubrifikues me cilësi të lartë dhe ruajtjen e sistemeve të filtrimit të ajrit të pastër. Turbokarikuesi funksionon në shpejtësi dhe temperatura shumë të larta, gjë që e bën veçanërisht të ndjeshëm ndaj cilësisë së vajit dhe ndërprerjeve të furnizimit me të. Kontrolli i rregullt i komponentëve të turbokarikuesit dhe i sistemeve shoqëruese mund të zbulojë probleme që po zhvillohen para se të ndodhë dështimi katastrofik.

Furnizimi me Vaj dhe Lubrifikimi

Lubrifikimi i duhur është absolutisht kritik për jetëgjatësinë dhe performancën e turbinkarburatorit në çdo aplikim motori cummins. Boshti i turbinkarburatorit funksionon me shpejtësi që kalojnë 100,000 RPM, ndërkohë që ekspozohet ndaj temperaturave të larta nga gazrat e nxehtë të shkarkimit dhe ajri i ngjeshur. Mungesa e furnizimit me vaj, vaji i ndotur ose qarkullimi i vonuar i vajit gjatë nisjes mund të dëmtojnë shpejt lagështirat dhe sigalet e turbinkarburatorit, duke çuar në riparime të shtrena dhe dëmtime potenciale të motorit nga humbja e vajit ose kontaminimi me copëza.

Ruajtja e lubrifikimit optimal të turbinkarburatorit kërkon përdorimin e gradeve të vajit të specifikuara nga prodhuesi, respektimin e intervaleve të rekomanduara të ndërrimit dhe sigurimin e presionit të duhur të vajit gjatë tërë gamës së funksionimit. Sistemet paralubrifikuese mund të jenë të dobishme për aplikimet me nisje dhe ndalesa të shpeshta, ndërsa programet e analizës së vajit mund të ofrojnë paralajmërim të herëshëm për probleme që po zhvillohen të lidhura me lubrifikimin para se të shkaktojnë dëmtime të turbinkarburatorit.

Shqetësimet për Marrjen e Ajrit dhe Filttrimin

Kufizimi i Filtërave të Ajrit

Problemet e filtrimit të ajrit mund të zvogëlojnë në mënyrë të konsiderueshme performancën dhe efikasitetin e çdo motori cummins duke kufizuar rrjedhën e ajrit drejt kamerave të djegies. Filtrot e bllokuar ose të ndotur rrisin kufizimin e hyrjes, duke i detyruar motorin të funksionojë më shumë për të thithur volumin e nevojshëm të ajrit për një djegie të duhur. Kjo ngarkesë e shtuar mund të rezultojë në zvogëlimin e prodhimit të energjisë, konsumim të rritur të karburantit, temperatura më të larta të gazeve të shkarkimit dhe mëkatje të nxituar të motorit për shkak të djegies së paplotë dhe shtimit të shtypjeve në cilindër.

Inspektimi i rregullt dhe zëvendësimi i filtrit të ajrit sipas kushteve të funksionimit dhe rekomandimeve të prodhuesit është thelbësor për ruajtjen e performancës optimale të motorit. Në mjedise të pluhur ose të ndotura, mund të jetë e nevojshme zëvendësimi më i shpeshtë i filtrit për të parandaluar grumbullimin e pengesave. Gajat e kufizimit të filtrit të ajrit mund të ofrojnë monitorim në kohë reale të gjendjes së filtrit, duke lejuar operatorët të optimizojnë intervalet e zëvendësimit bazuar në kushtet aktuale të funksionimit, në vend se në periudha arbitrare kohore.

Probleme të kolektorit të marrjes

Problemet e kolektorit të marrjes mund të ndikojnë në shpërndarjen e ajrit dhe në performancën e përgjithshme të motorit në instalimet e motorrave Cummins. Problemet mund të përfshijnë pjesë të çarëra të kolektorit, lidhje të lira, grumbullim karboni ose sipërfaqe të dëmtuara të paketave që lejojnë rrjedhje ajri ose kufizojnë shpërndarjen e duhur të ajrit në cilindrat individualë. Këto probleme mund të rezultojnë në performancë të papajtueshme të cilindrave, zvogëlim të prodhimit të përgjithshëm të fuqisë dhe rritje të emetimeve për shkak të raporteve të papërshtatshme të përzierjes ajër-detyrë.

Inspektimi i pjesëve të kolektorit të marrjes duhet të përfshijë kontrollin për çarje, korrozion ose dëmtime në sipërfaqet e montimit dhe diafragmat. Ndryshkimi i karbonit në sipërfaqet e marrjes mund të hiqet duke përdorur metoda të përshtatshme pastrimi dhe tretës që janë projektuar për pjesët e motorrit. Mirëmbajtja e rregullt e pjesëve të sistemit të marrjes ndihmon në sigurimin e shpërndarjes së duhur të ajrit dhe efikasitetit optimal të djegies në të gjitha cilindrat e motorrit.

FAQ

Sa shpesh duhet të kryej mirëmbajtje parandaluese në motorin tim Cummins

Intervallet e mirëmbajtjes parandaluese për motorët Cummins varen nga disa faktorë, përfshirë modelin e motorit, kushtet e funksionimit, ciklin e detyrës dhe cilësinë e karburantit. Në përgjithësi, ndryshimi i vajit duhet të kryhet çdo 10,000 deri në 15,000 mil për aplikimet në autostradë ose çdo 250 deri në 500 orë funksionimi për aplikimet stacionare. Filtrot e karburantit zakonisht kërkojnë zëvendësim çdo 10,000 deri në 20,000 mil, ndërsa filtrimet ajrore duhet të kontrollohen çdo 5,000 mil dhe të zëvendësohen sipas nevojës bazuar në nivelet e kufizimit. Mirëmbajtja e sistemit të ftohjes, përfshirë zëvendësimin e termostatit dhe gypave, duhet të kryhet sipas specifikimeve të prodhuesit, zakonisht çdo 100,000 mil ose 3,000 orë funksionimi.

Cilat janë shenjat paralajmëruese që motori im Cummins ka nevojë për vëmendje menjëhershe

Shenjat paralajmëruese kritike që kërkojnë vëmendje menjëhershe përfshijnë humbjen e papritur të fuqisë së motorit, zhurma të pazakonta të motorit si tinguj dërrmimi ose grirje, rritje të shpejtë të temperaturës, tym i tepërt nga mbarëvajtja (i bardhë, i blu ose i zi), drita paralajmëruese e presionit të vajit, humbja e lëngut për ftohje pa rrjedhje të dukshme dhe çdo kod gabimi i shfaqur nga sistemi i kontrollit të motorit. Për më tepër, vibracione të pazakonta, ndryshime në konsumin e karburantit ose vështirësi në nisje duhet të shtyjnë një vlerësim diagnostik menjëherë. Paragjykimi i këtyre shenjave paralajmëruese mund të çojë në dështim katastrofik të motorit dhe në kosto riparimesh shumë më të larta.

A mund të përdor pjesë të tregut alternativ për riparimin e motorëve Cummins

Ndërsa pjesët e pas-tregut mund të jenë të përshtatshme për disa aplikime motorrash Cummins, cilësia dhe përputhshmëria e këtyre komponentëve ndryshon në mënyrë të konsiderueshme midis prodhuesve. Për komponentët kritikë si injektorët e naftës, turbo-ndezësit dhe modulat e kontrollit të motorrave, rendimenti është zakonisht më i mirë kur përdoren pjesë origjinale Cummins, pasi këto komponentë kalibrohen veçanërisht për performancë dhe besnikëri optimale. Për komponentë më pak kritikë si filtra, rripa dhe artikuj rutinë mirëmbajtjeje, alternativat e pas-tregut me cilësi të lartë mund të ofrojnë performancë të pranueshme me kosto të ulur. Sigurohuni gjithmonë që pjesët e pas-tregut plotësojnë ose tejkalojnë specifikimet OEM dhe mbajnë garanci të duhura.

Si mund ta përmirësoj efikasitetin në harxhimin e naftës së motorrit tim Cummins

Përmirësimi i efikasitetit të karburantit në motorët Cummins kërkon një qasje të plotë që përfshin mirëmbajtje të rregullt, teknika të duhura të funksionimit dhe optimizim të sistemit. Sigurohuni që të gjitha filtra janë të pastër dhe zëvendësohen sipas planit, ruani shtypjen e duhur të gomat dhe aerodinamikën e mjetit, dhe shmangni ngrirjen e tepërt. Përshtatja dhe kalibrimi i motorit duhet të optimizohen për aplikimin specifik dhe kushtet e funksionimit. Programet e trajnimit të shoferëve mund të përmirësojnë ndjeshëm ekonominë e karburantit përmes teknikave të duhura të nxitjes, ndryshimit të marshit dhe menaxhimit të ngarkesës. Për më tepër, zbatimi i monitorimit të cilësisë së karburantit dhe përdorimi i naftës së cilësisë së lartë me aditivët e duhur mund të përmirësojnë efikasitetin e djegies dhe të reduktojnë konsumin e karburantit.

Përmbajtja

- Probleme të Lidhura me Sistemin e Karburantit

- Komplikime të Sistemit të Ftohjes

- Dëmtime të Sistemit Elektrik

- Probleme të Lidhura me Turbokompresorin

- Shqetësimet për Marrjen e Ajrit dhe Filttrimin

-

FAQ

- Sa shpesh duhet të kryej mirëmbajtje parandaluese në motorin tim Cummins

- Cilat janë shenjat paralajmëruese që motori im Cummins ka nevojë për vëmendje menjëhershe

- A mund të përdor pjesë të tregut alternativ për riparimin e motorëve Cummins

- Si mund ta përmirësoj efikasitetin në harxhimin e naftës së motorrit tim Cummins