Proper maintenance of industrial engines is fundamental to ensuring optimal performance, longevity, and cost-effective operation across various applications. A well-maintained diesel engine assembly can deliver decades of reliable service when subjected to systematic care protocols and preventive maintenance schedules. Understanding the critical components and maintenance requirements helps operators maximize their equipment investment while minimizing unexpected downtime and costly repairs.

Industrial diesel engines power countless applications from construction equipment to marine vessels, agricultural machinery to power generation systems. Each diesel engine assembly requires specific maintenance protocols tailored to its operational environment and duty cycle. Regular maintenance not only preserves engine performance but also ensures compliance with emission standards and safety regulations that govern industrial equipment operation.

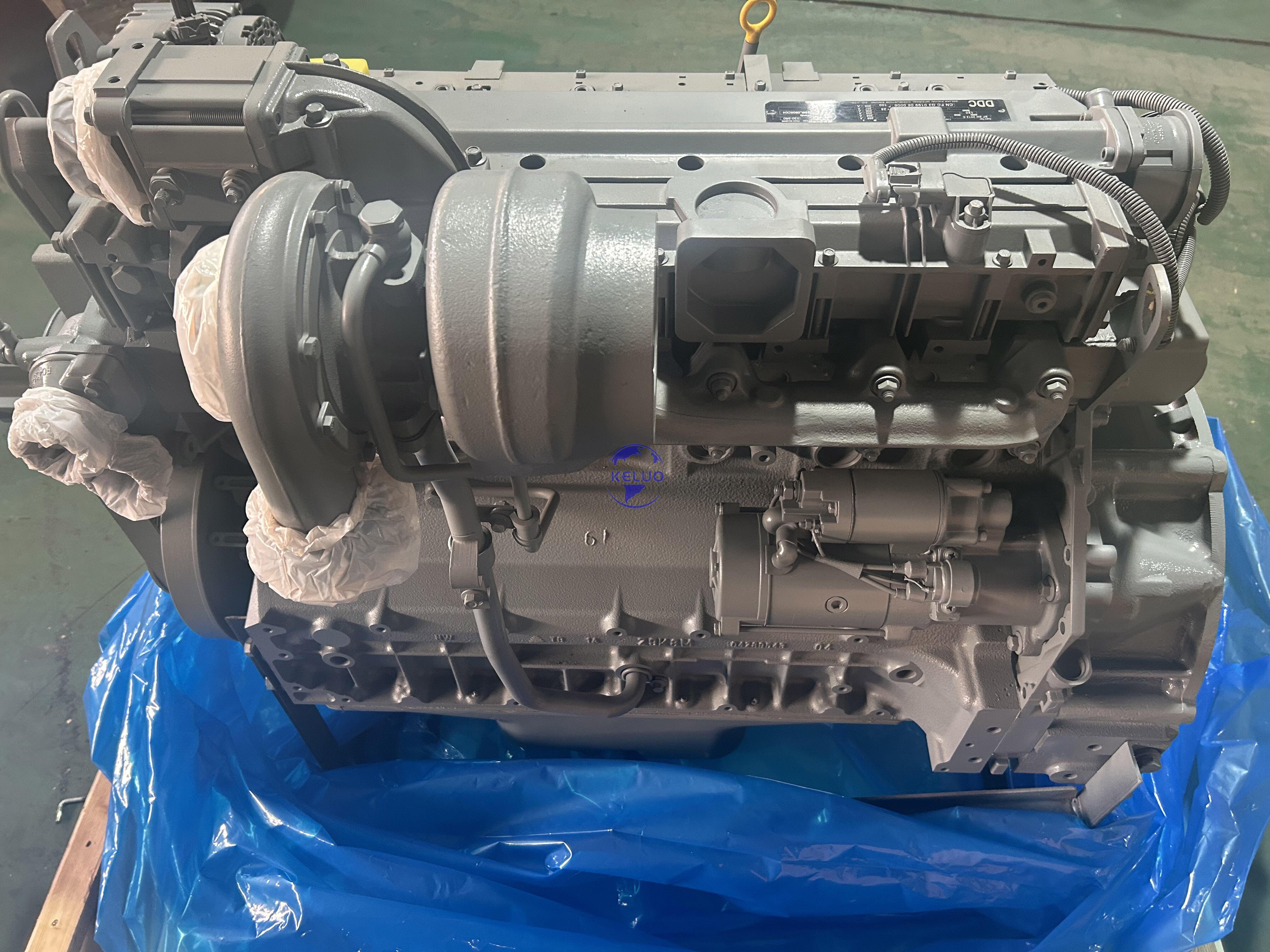

The complexity of modern diesel engine assembly systems demands comprehensive understanding of various subsystems including fuel injection, cooling, lubrication, and emission control components. Maintenance programs must address each system systematically to prevent cascading failures that can result in catastrophic engine damage. Professional maintenance protocols have evolved significantly with advances in engine technology, requiring updated approaches to traditional servicing methods.

Fundamental Engine Inspection Procedures

Visual Assessment and External Components

Beginning any maintenance routine requires thorough visual inspection of the diesel engine assembly external components. Operators should examine all visible surfaces for signs of fluid leaks, corrosion, physical damage, or unusual wear patterns that may indicate underlying mechanical issues. The engine block, cylinder head, and associated mounting hardware should be inspected for cracks, loose fasteners, or deteriorating gaskets that could compromise engine integrity.

External components including the alternator, starter motor, fuel lines, and electrical connections require careful examination during routine inspections. Any signs of oil contamination, fuel seepage, or electrical corrosion should be documented and addressed promptly to prevent system failures. The inspection process should follow a systematic checklist approach to ensure consistent coverage of all critical areas.

Air intake systems and exhaust components form integral parts of the diesel engine assembly that directly impact performance and emissions compliance. Visual inspection should include examination of air filter housings, intake ducting, exhaust manifolds, and associated piping for damage, blockages, or deterioration. These components often provide early warning signs of internal engine problems when abnormal conditions are detected during regular inspections.

Internal System Evaluation

Internal system evaluation requires specialized knowledge and appropriate diagnostic equipment to assess the condition of critical engine components. Compression testing, oil analysis, and cooling system pressure tests provide valuable insights into diesel engine assembly internal condition without requiring complete disassembly. These diagnostic procedures help identify developing problems before they result in major component failures.

Oil sampling and analysis programs offer comprehensive evaluation of engine internal condition through laboratory testing of lubricant samples. Analysis results reveal information about bearing wear, fuel dilution, coolant contamination, and particulate contamination that indicates specific maintenance requirements. Regular oil analysis enables predictive maintenance approaches that optimize service intervals and prevent unexpected failures.

Cooling system evaluation includes testing coolant concentration, pH levels, and corrosion inhibitor effectiveness to ensure proper heat transfer and component protection. The diesel engine assembly cooling system must maintain precise temperature control to optimize combustion efficiency while protecting components from thermal stress. Regular testing and maintenance of cooling system components prevents overheating conditions that can cause severe engine damage.

Lubrication System Maintenance

Oil Selection and Change Intervals

Proper lubrication forms the foundation of effective diesel engine assembly maintenance, requiring careful selection of appropriate oil grades and adherence to recommended change intervals. Modern diesel engines operate under increasingly demanding conditions that place greater stress on lubricating oils, necessitating premium quality products that meet or exceed manufacturer specifications. Oil selection must consider operating temperature ranges, load factors, and environmental conditions specific to each application.

Change interval determination depends on multiple factors including operating conditions, fuel quality, and oil analysis results rather than relying solely on manufacturer recommendations. Severe service applications may require more frequent oil changes to maintain adequate lubrication and component protection. Monitoring oil condition through regular sampling and analysis provides the most accurate method for determining optimal change intervals for each specific diesel engine assembly.

High-quality synthetic and semi-synthetic lubricants offer superior protection and extended service intervals compared to conventional mineral oils in many applications. These advanced lubricants provide better thermal stability, oxidation resistance, and low-temperature flow characteristics that benefit diesel engine assembly operation. However, cost considerations and compatibility with existing sealing materials must be evaluated when considering lubricant upgrades.

Filter System Management

Oil filter systems play crucial roles in maintaining lubricant cleanliness and protecting diesel engine assembly components from contamination damage. Filter selection should prioritize filtration efficiency and dirt-holding capacity appropriate for specific operating conditions and service intervals. Premium quality filters often provide better protection and longer service life, justifying their higher initial cost through reduced maintenance requirements.

Filter change procedures must follow proper protocols to prevent contamination introduction during service operations. Clean working conditions, proper tools, and attention to detail during filter installation ensure maximum benefit from new filtration components. Double-checking gasket placement, proper torque application, and system priming prevents common installation errors that can compromise filtration system effectiveness.

Bypass filtration systems offer additional protection for diesel engine assembly lubrication systems by providing continuous fine filtration of circulating oil. These supplemental systems remove smaller particles and contaminants that may pass through full-flow filters, extending oil life and improving component protection. Bypass filtration becomes particularly valuable in severe service applications where contamination levels exceed normal operating conditions.

Fuel System Optimization

Fuel Quality Management

Fuel quality directly impacts diesel engine assembly performance, emissions compliance, and component longevity, making fuel system maintenance a critical aspect of overall engine care. Poor quality fuel containing excessive water, particulates, or microbial growth can cause injection system damage, fuel system corrosion, and combustion problems that significantly reduce engine life. Establishing fuel quality standards and testing protocols helps ensure consistent fuel quality for optimal engine operation.

Water contamination represents one of the most common fuel quality issues affecting diesel engine assembly operation. Water promotes microbial growth, accelerates corrosion, and can cause injection system damage through cavitation and poor lubrication. Regular water separation and fuel tank maintenance practices help minimize water-related problems while fuel additives can provide additional protection against contamination issues.

Fuel storage and handling practices significantly impact fuel quality and diesel engine assembly reliability. Proper tank design, regular cleaning, and appropriate fuel rotation help maintain fuel quality during storage periods. Fuel testing programs should monitor key parameters including water content, particulate levels, and microbial contamination to identify quality issues before they impact engine operation.

Injection System Service

Modern diesel injection systems operate at extremely high pressures and precise tolerances that require specialized maintenance procedures and equipment. The diesel engine assembly injection system must deliver precise fuel quantities at exact timing intervals to optimize combustion efficiency and emissions compliance. Regular injection system service helps maintain performance while preventing costly component failures.

Fuel filter maintenance becomes critically important for injection system protection, requiring regular replacement of primary and secondary filters according to manufacturer specifications. Filter bypass conditions can allow contaminated fuel to reach sensitive injection components, causing rapid wear and performance degradation. Premium quality filters with appropriate micron ratings provide essential protection for modern high-pressure injection systems.

Injection timing and fuel delivery calibration require specialized diagnostic equipment and trained technicians to ensure proper adjustment. Incorrect timing or fuel delivery rates can cause excessive emissions, poor fuel economy, and accelerated engine wear. Regular calibration verification helps maintain optimal diesel engine assembly performance while ensuring compliance with applicable emission standards.

Cooling System Maintenance

Coolant Management

Effective cooling system maintenance ensures proper thermal management of diesel engine assembly components while preventing corrosion and scaling that can impair heat transfer efficiency. Coolant selection must consider the specific requirements of engine materials, operating conditions, and environmental factors that influence cooling system performance. Modern engines often require extended-life coolants with advanced additive packages designed for specific applications.

Coolant testing programs should monitor pH levels, freeze point protection, corrosion inhibitor concentration, and contamination levels to ensure continued cooling system effectiveness. Regular testing enables proactive maintenance decisions that prevent cooling system problems before they impact diesel engine assembly operation. Laboratory analysis provides detailed information about coolant condition and remaining service life.

Cooling system flushing and refill procedures must follow manufacturer specifications to ensure complete removal of old coolant and proper filling without air pockets. Improper flushing can leave contaminated coolant residue that reduces new coolant effectiveness, while inadequate filling procedures can create air pockets that cause hot spots and component damage. Professional service procedures help ensure cooling system maintenance quality.

Heat Exchanger Service

Heat exchanger maintenance includes regular cleaning and inspection of radiators, oil coolers, and intercoolers that remove heat from various diesel engine assembly systems. External cleaning removes debris, insects, and contamination that reduce heat transfer efficiency and increase operating temperatures. Internal cleaning may be required when coolant contamination or scaling affects heat exchanger performance.

Thermostat operation verification ensures proper cooling system temperature control that optimizes engine efficiency while preventing overcooling or overheating conditions. Faulty thermostats can cause extended warm-up periods, inefficient operation, or overheating that damages engine components. Regular thermostat testing and replacement according to maintenance schedules helps maintain proper temperature control.

Cooling system pressure testing identifies leaks, weak components, and pressure cap effectiveness that could compromise cooling system operation. Pressure testing should be performed regularly to detect developing problems before they result in coolant loss or overheating conditions. Early detection of cooling system problems prevents costly engine damage from thermal stress.

Air System Maintenance

Air Filter Service

Air filtration systems protect diesel engine assembly internal components from abrasive particles that cause accelerated wear and performance degradation. Proper air filter selection, installation, and service intervals are essential for maintaining engine protection while ensuring adequate airflow for optimal combustion. Filter restriction monitoring helps optimize service intervals based on actual operating conditions rather than arbitrary time periods.

Multi-stage air filtration systems require coordinated maintenance of primary and secondary filter elements to maintain system effectiveness. Servicing procedures must prevent contamination introduction while ensuring proper sealing and installation of replacement filters. Quality filter elements provide superior protection and longer service life compared to economy alternatives, justifying their higher cost through improved engine protection.

Air intake system inspection should include ducting, connections, and housing components that could allow unfiltered air to enter the diesel engine assembly. Even small leaks can introduce significant contamination that bypasses filtration systems and causes internal engine damage. Regular inspection and maintenance of air intake system integrity ensures continued protection from airborne contaminants.

Turbocharger Maintenance

Turbocharged diesel engine assembly systems require specific maintenance procedures to ensure turbocharger longevity and optimal performance. Turbocharger operation depends on clean oil supply, proper operating temperatures, and gradual shutdown procedures that prevent thermal shock damage. Understanding turbocharger operational requirements helps operators avoid common practices that cause premature turbocharger failure.

Oil supply system maintenance becomes critically important for turbocharger protection, requiring clean oil, adequate pressure, and proper drain-back provisions. Contaminated oil or inadequate lubrication can cause turbocharger bearing failure within minutes of operation. Regular oil changes and filter service help ensure turbocharger lubrication system effectiveness throughout the service interval.

Turbocharger inspection procedures include checking for oil leaks, unusual noise, excessive play in rotating assemblies, and proper boost pressure development. Early detection of turbocharger problems enables repair before complete failure occurs, often saving significant costs compared to replacement requirements. Professional diagnostic equipment helps evaluate turbocharger condition accurately.

Electrical System Care

Battery and Charging System

Electrical system maintenance ensures reliable starting and proper operation of diesel engine assembly control systems, instrumentation, and accessories. Battery maintenance includes regular testing, cleaning, and electrolyte level checks that prevent starting problems and electrical system failures. Modern engines with electronic controls place greater demands on electrical systems, requiring higher standards of maintenance and component quality.

Charging system performance verification ensures adequate electrical generation to maintain battery charge and operate electrical accessories. Alternator output testing, belt tension adjustment, and connection cleaning help maintain charging system effectiveness. Inadequate charging can cause battery failure and electronic control system malfunctions that impact diesel engine assembly operation.

Electrical connection maintenance includes cleaning, tightening, and protecting connections from corrosion and environmental damage. Poor connections create voltage drops, heat generation, and intermittent operation that can cause control system problems and component failures. Regular electrical system inspection and maintenance prevents many common electrical problems.

Control System Diagnostics

Modern diesel engine assembly control systems provide sophisticated monitoring and diagnostic capabilities that enable predictive maintenance and problem identification. Electronic control modules store fault codes and operational data that help technicians diagnose problems and optimize engine performance. Regular diagnostic system checks help identify developing problems before they cause operational failures.

Sensor calibration and testing ensure accurate engine monitoring and control system operation. Faulty sensors can cause incorrect engine operation, poor fuel economy, and excessive emissions that may violate regulatory requirements. Professional diagnostic equipment enables comprehensive sensor testing and calibration verification for optimal control system performance.

Software updates and parameter adjustments may be required to maintain optimal diesel engine assembly performance and compliance with changing regulations. Manufacturer service bulletins and technical updates provide information about available improvements and required modifications. Regular communication with service providers helps ensure engines receive necessary updates and modifications.

FAQ

How often should diesel engine oil be changed

Oil change intervals for diesel engine assembly systems depend on operating conditions, oil quality, and manufacturer recommendations, typically ranging from 250 to 500 operating hours for standard applications. Severe service conditions including high ambient temperatures, dusty environments, or frequent starts may require more frequent oil changes. Oil analysis programs provide the most accurate method for determining optimal change intervals based on actual oil condition rather than arbitrary time periods.

What are the signs of cooling system problems

Common indicators of cooling system problems include elevated operating temperatures, coolant loss, white exhaust smoke, and external coolant leaks around engine components. Internal coolant leaks may cause oil contamination, creating a milky appearance in engine oil or excessive crankcase pressure. Regular temperature monitoring and coolant level checks help identify cooling system problems before they cause serious diesel engine assembly damage.

How can fuel quality issues be prevented

Preventing fuel quality problems requires proper fuel storage, regular tank cleaning, water removal, and fuel testing programs that monitor contamination levels. Quality fuel suppliers, appropriate storage tank design, and fuel additives help maintain fuel quality during storage periods. Regular filter changes and water separation system maintenance protect diesel engine assembly fuel injection components from contamination damage.

When should professional engine service be performed

Professional diesel engine assembly service should be performed when diagnostic tests indicate developing problems, during major maintenance intervals, or when operators lack the equipment and expertise for complex procedures. Injection system service, turbocharger maintenance, and electronic system diagnostics typically require specialized equipment and training. Regular professional inspections help identify problems that may not be apparent during routine operator maintenance procedures.