When investing in heavy-duty equipment or industrial machinery, understanding the longevity and reliability of your power source becomes crucial for operational success. The cummins engine has established itself as a benchmark in the diesel engine industry, renowned for exceptional durability and performance across diverse applications. From construction equipment to marine vessels, these powerplants deliver consistent service that spans decades when properly maintained. Equipment operators and fleet managers worldwide rely on Cummins technology to minimize downtime and maximize productivity in demanding industrial environments.

The reputation of Cummins engines extends far beyond simple marketing claims, backed by decades of real-world performance data and engineering excellence. Understanding the factors that influence engine longevity helps operators make informed decisions about maintenance schedules, operating procedures, and equipment investments. Modern Cummins powerplants incorporate advanced materials science, precision manufacturing, and sophisticated control systems that significantly extend operational life compared to older generation engines.

Understanding Cummins Engine Durability Standards

Engineering Excellence and Build Quality

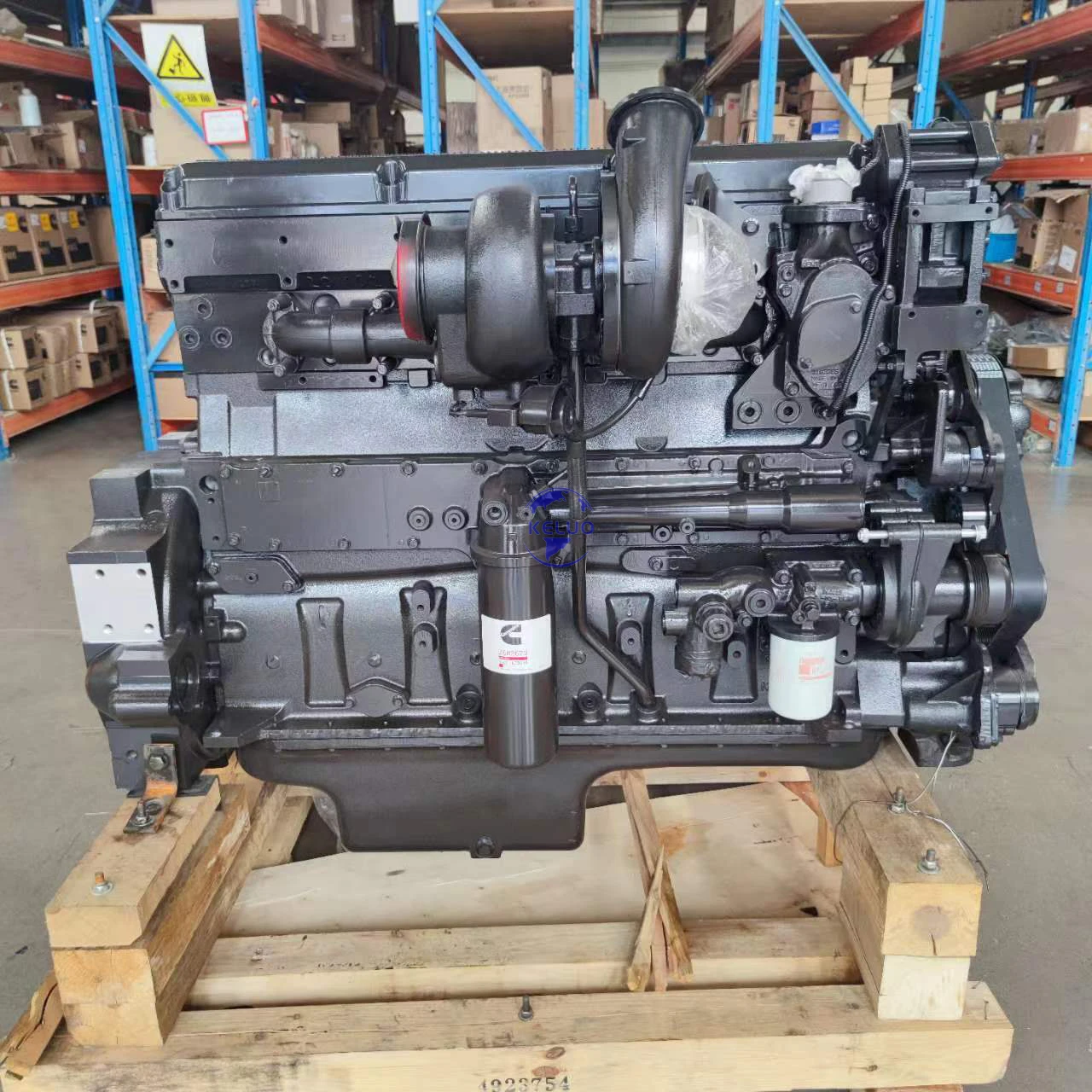

Cummins engines achieve exceptional longevity through meticulous engineering processes that prioritize durability from the initial design phase. The company employs advanced metallurgy techniques, creating engine blocks and components from high-strength cast iron and specialized alloy materials that resist wear under extreme conditions. Each cummins engine undergoes rigorous quality control testing, including stress analysis, thermal cycling, and endurance testing that simulates years of operational demands within compressed timeframes.

Manufacturing precision plays a critical role in determining engine lifespan, with Cummins facilities maintaining tolerances measured in thousandths of inches across critical components. Advanced machining centers and automated assembly processes ensure consistent quality across production runs, eliminating variations that could compromise long-term reliability. The integration of computer-controlled manufacturing systems allows for real-time quality monitoring and immediate correction of any deviations from specified parameters.

Material Science Innovations

The selection of materials in Cummins engine construction directly impacts operational longevity and maintenance requirements. Engine blocks utilize compacted graphite iron, which provides superior strength-to-weight ratios compared to traditional gray iron while maintaining excellent thermal conductivity for efficient heat dissipation. Critical wear surfaces receive specialized treatments including plasma nitriding and diamond-like carbon coatings that dramatically reduce friction and extend component life.

Advanced bearing materials incorporate polymer overlays and specialized alloys designed to withstand extreme pressures and temperatures encountered in high-performance diesel applications. These innovations allow Cummins engines to operate reliably under conditions that would quickly degrade lesser powerplants, contributing significantly to extended service intervals and reduced maintenance costs over the engine's operational lifetime.

Typical Life Expectancy Ranges

Heavy-Duty Applications

In heavy-duty applications such as long-haul trucking and construction equipment, a properly maintained cummins engine typically achieves between 800,000 to 1.2 million miles of service before requiring major overhaul. These impressive figures represent real-world performance under demanding conditions including frequent load cycles, temperature extremes, and continuous operation schedules. Fleet operators consistently report that Cummins powerplants exceed initial life expectancy projections when operated within manufacturer specifications and maintained according to recommended schedules.

The ISX15 and X15 engine families have demonstrated exceptional longevity in over-the-road applications, with many units surpassing one million miles without major internal work. These achievements result from advanced fuel injection systems, optimized combustion chamber designs, and sophisticated engine management systems that continuously monitor and adjust operating parameters to minimize wear and maximize efficiency throughout the engine's operational life.

Industrial and Marine Applications

Industrial stationary applications often see even greater longevity from Cummins engines due to consistent operating conditions and reduced thermal cycling compared to mobile applications. Generator sets and industrial pump applications frequently achieve 40,000 to 60,000 operating hours before requiring major maintenance, equivalent to decades of service in typical duty cycles. Marine applications present unique challenges but still deliver impressive service lives when engines receive proper cooling system maintenance and fuel quality management.

The QSK series engines designed for heavy industrial use incorporate robust construction features specifically engineered for continuous duty applications. These powerplants utilize reinforced engine blocks, heavy-duty cooling systems, and oversized bearing surfaces that distribute loads across larger areas, reducing stress concentrations that could limit operational life in demanding industrial environments.

Key Factors Affecting Engine Longevity

Maintenance Protocol Adherence

Consistent adherence to manufacturer-specified maintenance protocols represents the single most important factor in achieving maximum cummins engine life expectancy. Regular oil changes using approved lubricants maintain proper lubrication film thickness and remove combustion byproducts that could accelerate component wear. Filter replacements at specified intervals ensure clean fuel delivery and adequate airflow, preventing contaminants from reaching critical engine internals.

Advanced diagnostic systems in modern Cummins engines provide real-time monitoring of critical parameters including oil pressure, coolant temperature, and exhaust gas temperatures. These systems alert operators to developing problems before they result in catastrophic failures, allowing for preventive maintenance that extends engine life significantly beyond what was possible with older generation powerplants lacking such sophisticated monitoring capabilities.

Operating Conditions and Environment

Environmental factors significantly influence engine longevity, with dust, humidity, temperature extremes, and altitude all playing important roles in determining service life. Cummins engines operating in clean, controlled environments typically achieve longer service intervals compared to units subjected to dusty construction sites or corrosive marine atmospheres. Proper air filtration becomes critical in dusty environments, as abrasive particles can cause accelerated wear of cylinder walls and piston rings if allowed to enter the combustion chamber.

Operating altitude affects engine performance and longevity due to reduced air density at higher elevations, requiring deration of power output to maintain acceptable exhaust gas temperatures and prevent thermal stress. Cummins provides specific altitude correction factors and operating guidelines that help maintain engine reliability across diverse geographic and climatic conditions encountered in global industrial applications.

Maximizing Your Cummins Engine Investment

Preventive Maintenance Best Practices

Implementing comprehensive preventive maintenance programs maximizes the return on investment in cummins engine technology through extended service life and reduced unexpected downtime. Oil analysis programs provide valuable insights into internal engine condition, identifying potential problems through analysis of wear metals, fuel dilution, and contamination levels in used lubricants. These programs allow maintenance teams to address developing issues before they result in expensive component failures.

Cooling system maintenance proves equally critical, as overheating represents one of the primary causes of premature engine failure across all applications. Regular coolant analysis and replacement according to manufacturer specifications prevents corrosion and scaling that can restrict coolant flow and reduce heat transfer efficiency. Proper thermostat operation and radiator cleanliness ensure optimal operating temperatures under all load conditions.

Fuel Quality Management

Fuel quality directly impacts engine longevity through its effects on combustion efficiency, fuel system component wear, and deposit formation within the engine. Cummins engines perform best with clean, dry diesel fuel meeting ASTM specifications for sulfur content, cetane rating, and water contamination limits. Fuel polishing systems and water separation equipment help maintain fuel quality during storage and transfer operations, preventing contamination-related problems that could shorten engine life.

Modern common rail fuel injection systems operate at extremely high pressures, making them particularly sensitive to fuel contamination and water content. Regular fuel filter changes and fuel system cleaning help maintain injection system precision, ensuring optimal combustion that minimizes carbon deposits and extends component life throughout the fuel delivery system and combustion chambers.

Signs of Engine Aging and When to Consider Overhaul

Performance Indicators

Recognizing early warning signs of engine aging allows operators to plan maintenance activities and budget for major overhauls before unexpected failures occur. Gradual increases in oil consumption, reduced power output under load, and increased exhaust smoke production often indicate internal wear that may require attention. Modern engine monitoring systems track these parameters automatically, providing trend analysis that helps predict when major maintenance will become necessary.

Fuel consumption increases beyond normal parameters can indicate reduced combustion efficiency due to worn injectors, decreased compression ratios, or timing issues that develop as engines accumulate operating hours. Regular performance testing and comparison to baseline measurements help identify these trends before they result in significant operational costs or reliability issues that could impact productivity.

Diagnostic Technology Applications

Advanced diagnostic equipment provides detailed analysis of engine condition without requiring disassembly, allowing for accurate assessment of internal wear patterns and remaining service life. Cylinder leak-down testing, compression analysis, and electronic system diagnostics reveal the condition of critical components including pistons, rings, valves, and cylinder heads. These non-intrusive testing methods help determine whether engines can continue in service or require immediate attention.

Vibration analysis and acoustic monitoring detect bearing wear, timing gear problems, and other mechanical issues that may not be apparent through traditional diagnostic methods. These technologies enable predictive maintenance strategies that optimize engine replacement timing based on actual condition rather than arbitrary hour-based schedules, maximizing the useful life of expensive engine investments.

FAQ

What is the typical lifespan of a Cummins engine in hours

A well-maintained Cummins engine typically achieves 15,000 to 25,000 operating hours in heavy-duty applications before requiring major overhaul, though many units exceed these figures with proper care. Industrial applications often see 40,000 to 60,000 hours due to more consistent operating conditions. The actual lifespan depends heavily on maintenance practices, operating conditions, and load factors throughout the engine's service life.

How do I know when my Cummins engine needs major maintenance

Key indicators include increased oil consumption beyond normal parameters, reduced power output under standard loads, excessive exhaust smoke production, and unusual noise or vibration patterns. Modern diagnostic systems provide early warning through parameter monitoring, while oil analysis programs can detect internal wear before it becomes critical. Regular performance testing against baseline measurements helps identify declining efficiency trends.

Can a Cummins engine be rebuilt to like-new condition

Yes, Cummins engines are designed for complete rebuilding with factory-specification parts and procedures. A properly executed rebuild can restore engine performance to near-original levels and provide additional service life comparable to a new engine. The key lies in using genuine Cummins parts, following factory procedures, and addressing all worn components during the rebuild process rather than attempting partial repairs.

What factors most significantly impact Cummins engine longevity

Maintenance protocol adherence represents the most critical factor, followed by operating conditions, fuel quality, and load management. Regular oil changes with approved lubricants, proper cooling system maintenance, and clean fuel delivery systems prevent the majority of premature failures. Environmental factors such as dust exposure, temperature extremes, and operating altitude also play important roles in determining ultimate service life.