The agricultural and construction industries rely heavily on dependable power solutions, and Kubota has established itself as a leading manufacturer of high-performance diesel engines. Whether you're operating agricultural machinery, construction equ...

VIEW MORE

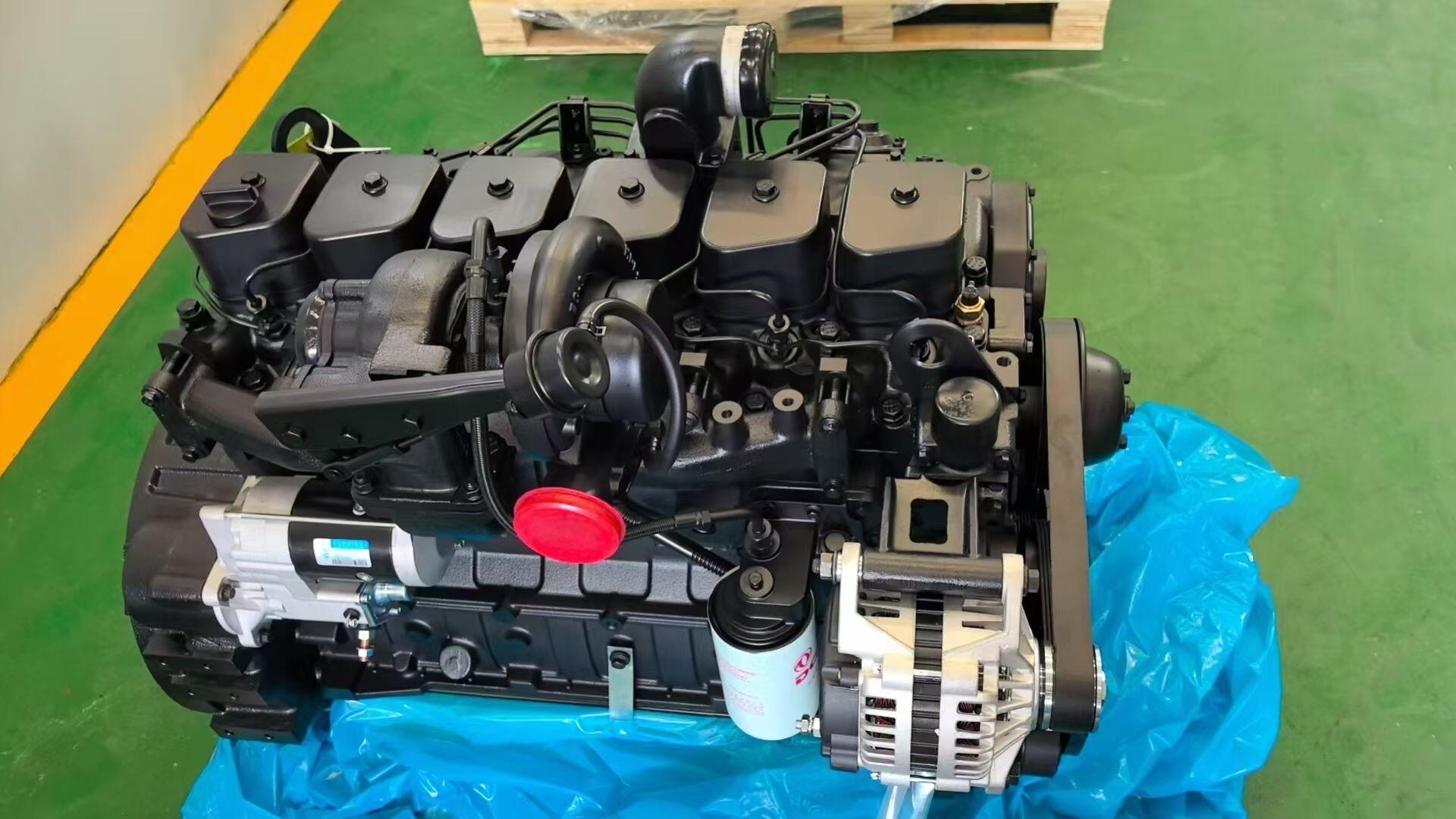

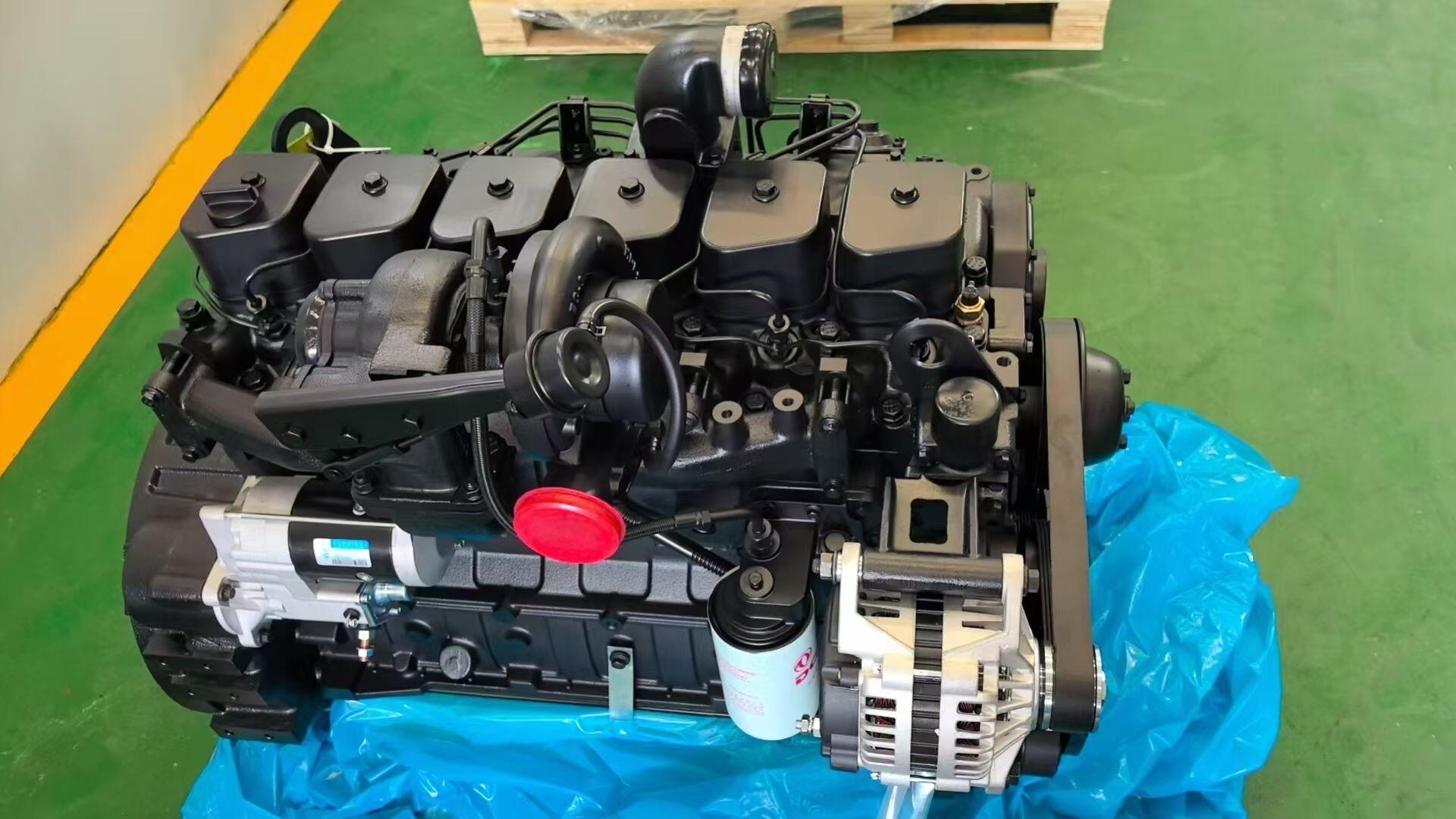

When evaluating heavy-duty power solutions for industrial applications, understanding comprehensive engine specifications becomes paramount for optimal performance outcomes. The modern industrial landscape demands reliable, efficient powertrains that...

VIEW MORE

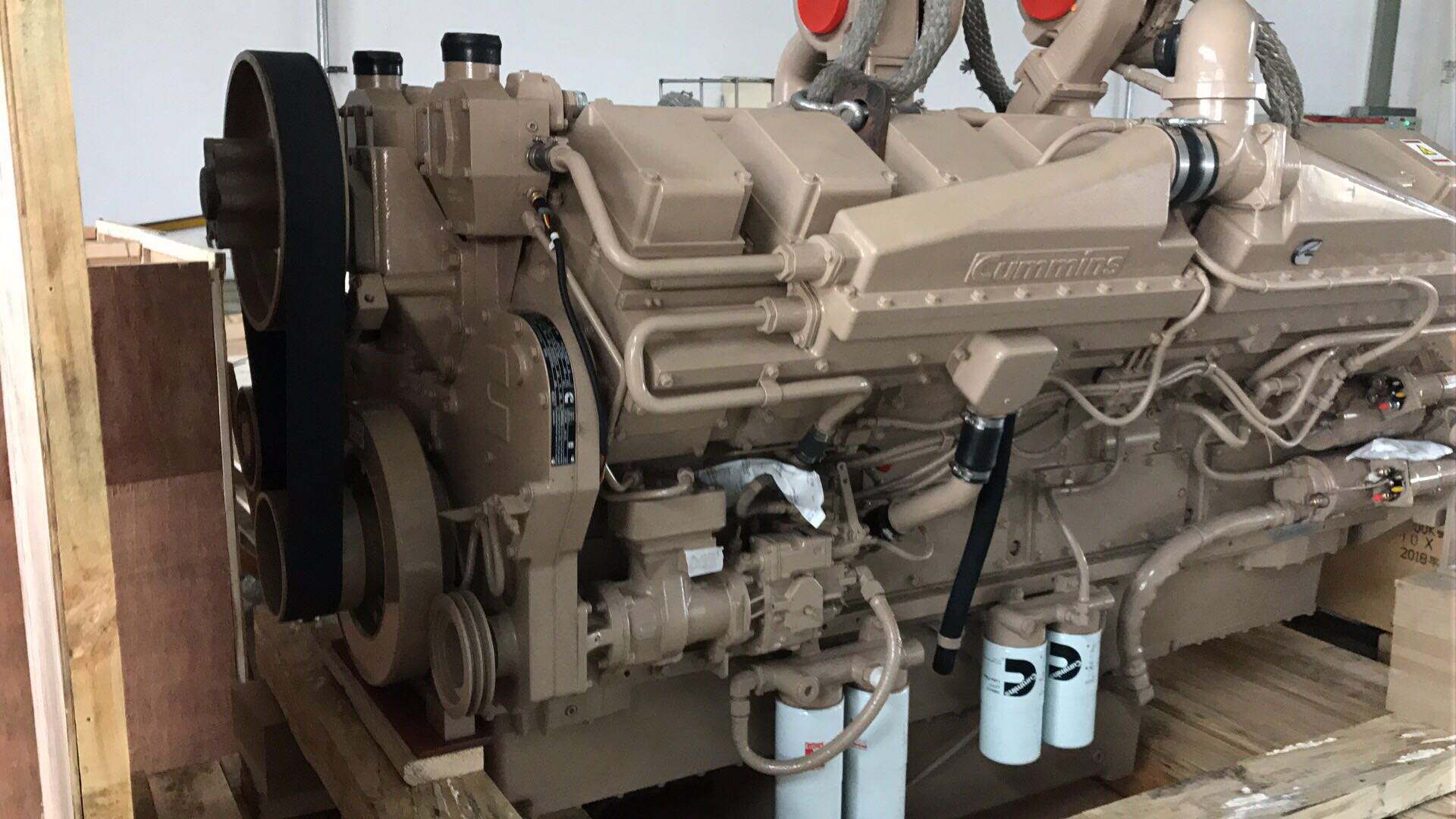

When it comes to powering heavy-duty trucks that demand exceptional performance and reliability, few manufacturers match the reputation and engineering excellence of Cummins. For decades, fleet operators, truck manufacturers, and independent drivers ...

VIEW MORE

When investing in heavy-duty equipment or industrial machinery, understanding the longevity and reliability of your power source becomes crucial for operational success. The cummins engine has established itself as a benchmark in the diesel engine in...

VIEW MORE

Proper maintenance is the cornerstone of extending the service life and ensuring optimal performance of your cummins engine. Whether powering marine vessels, trucks, or heavy machinery, these robust diesel engines demand systematic care to deliver re...

VIEW MORE

When it comes to reliable diesel power in industrial and commercial applications, the Isuzu engine has established itself as a cornerstone of dependable performance across multiple sectors. These robust powerplants have earned their reputation throug...

VIEW MORE

Cummins engines have earned their reputation as some of the most reliable and durable powerplants in commercial and industrial applications worldwide. However, like any complex mechanical system, these robust engines can experience various issues ove...

VIEW MORE

When selecting a reliable power solution for heavy-duty applications, understanding the comprehensive range of available options becomes crucial for operational success. The industrial landscape demands engines that deliver consistent performance, ex...

VIEW MOREThe Evolution of Marine Engineering Excellence The maritime industry has witnessed remarkable technological advancements over the decades, and at the forefront of this evolution stands the yanmar engine. With a legacy spanning over a century, these p...

VIEW MORE

Understanding the Legacy of Yanmar's Engineering Excellence When it comes to reliable power solutions, the yanmar engine stands as a testament to Japanese engineering prowess. With over a century of innovation and continuous improvement, Yanmar has e...

VIEW MORE

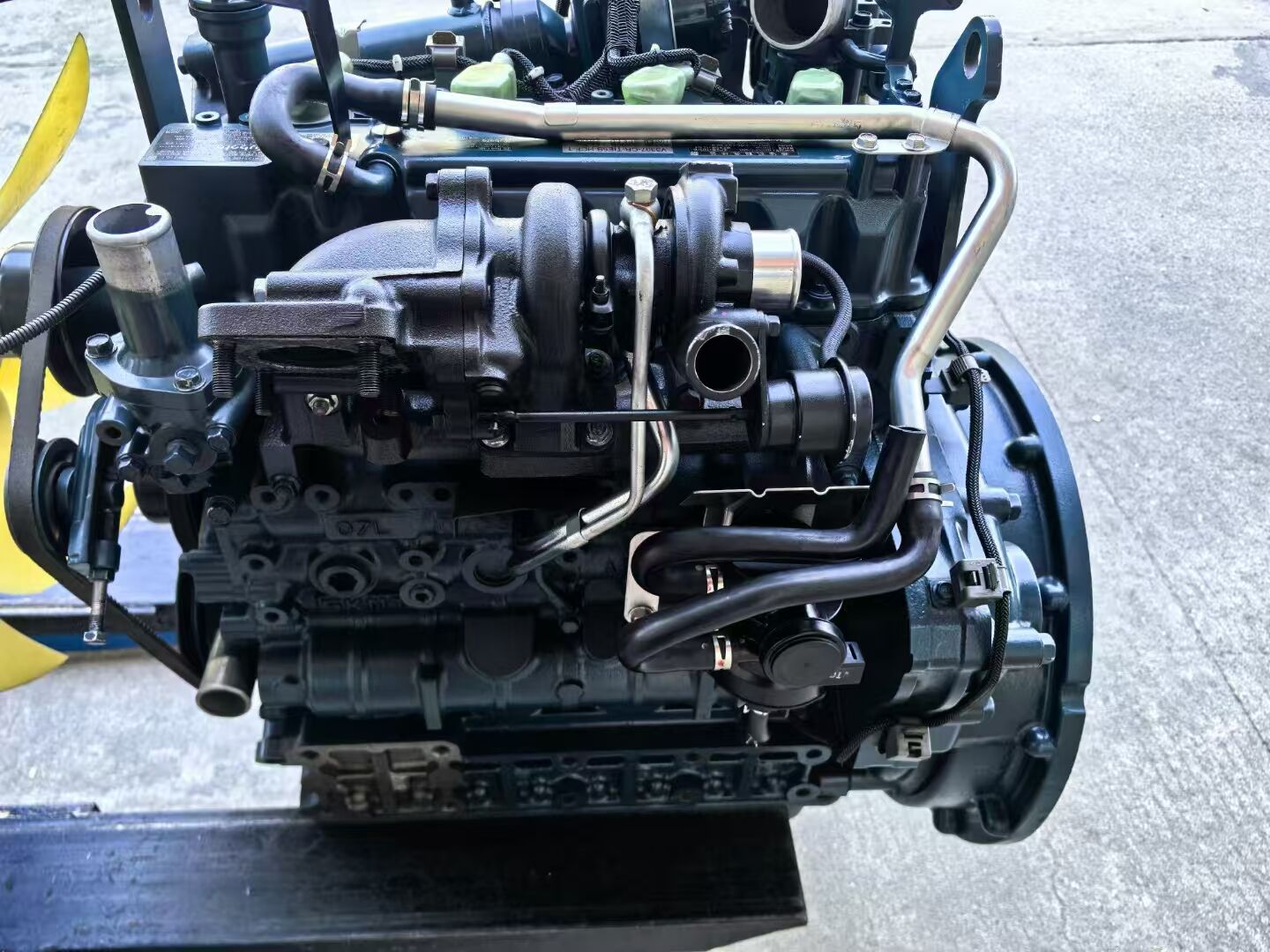

Maximizing Heavy Equipment Power and Efficiency The heart of any construction machinery lies in its excavator engine, determining not just the equipment's raw power but its overall efficiency and longevity. Whether managing a construction fleet or op...

VIEW MORE

Essential Guide to Common Yanmar Engine Issues and Expert Solutions Yanmar engines have earned a solid reputation for their reliability and performance in marine vessels, agricultural equipment, and industrial applications. However, like any mechanic...

VIEW MORE