When selecting a reliable power solution for heavy-duty applications, understanding the comprehensive range of available options becomes crucial for operational success. The industrial landscape demands engines that deliver consistent performance, exceptional durability, and cost-effective operation across diverse working conditions. Modern diesel engines have evolved significantly, incorporating advanced technologies that enhance fuel efficiency while reducing environmental impact. These powerplants serve as the backbone for numerous industries, from construction and mining to marine operations and power generation. Choosing the right engine requires careful consideration of power requirements, operational environment, maintenance schedules, and long-term reliability expectations.

Engine Performance Categories and Applications

Medium-Duty Engine Solutions

The medium-duty segment represents a versatile category designed for applications requiring balanced power output and fuel efficiency. These engines typically produce between 200 to 400 horsepower, making them ideal for delivery trucks, school buses, and smaller construction equipment. The engineering focus emphasizes reliability while maintaining reasonable operating costs, incorporating features like electronic fuel injection and advanced cooling systems. Operators appreciate the reduced maintenance intervals and improved diagnostic capabilities that come standard with modern medium-duty powerplants.

Advanced emission control technologies have revolutionized this category, enabling compliance with stringent environmental regulations without sacrificing performance. The integration of selective catalytic reduction systems and diesel particulate filters ensures clean operation while maintaining the robust power delivery expected from professional-grade engines. These technological improvements have extended service intervals and reduced total cost of ownership, making medium-duty engines an attractive option for fleet operators seeking long-term value.

Heavy-Duty Industrial Applications

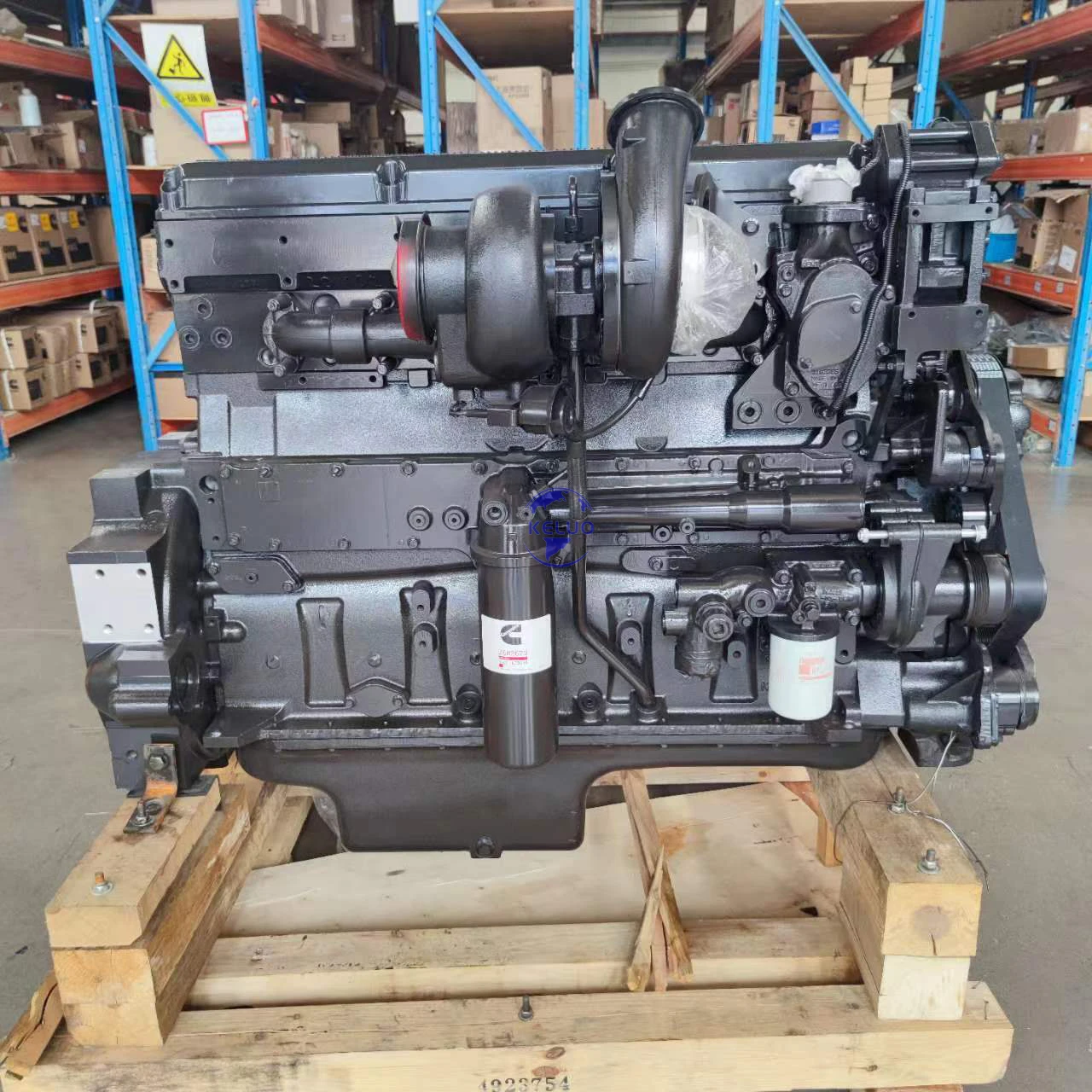

Heavy-duty industrial engines represent the pinnacle of diesel technology, designed to withstand extreme operating conditions while delivering exceptional power output. These robust powerplants typically range from 400 to over 2000 horsepower, serving critical roles in mining operations, large construction projects, and marine vessels. The engineering philosophy prioritizes maximum durability, with reinforced components and enhanced cooling systems capable of sustained high-load operation. Industrial operators rely on these engines for mission-critical applications where downtime translates directly to significant financial losses.

The sophisticated control systems integrated into heavy-duty engines provide real-time monitoring of critical parameters, enabling predictive maintenance strategies that minimize unexpected failures. Advanced turbocharging systems and precision fuel injection technologies optimize combustion efficiency, resulting in improved fuel economy despite the substantial power output. These engines often feature modular designs that facilitate field servicing and component replacement, reducing maintenance downtime and extending operational availability.

Technology Integration and Innovation

Electronic Control Systems

Modern engine management systems represent a significant advancement in diesel technology, incorporating sophisticated electronic controls that optimize performance across varying operating conditions. These intelligent systems continuously monitor hundreds of parameters, adjusting fuel delivery, timing, and boost pressure to maximize efficiency while protecting critical components. The integration of advanced sensors and actuators enables precise control of combustion processes, resulting in reduced emissions and improved fuel economy. Fleet managers benefit from comprehensive diagnostic capabilities that provide detailed insights into engine health and performance trends.

The connectivity features built into contemporary engines facilitate remote monitoring and fleet management capabilities. Telematics integration allows operators to track engine performance, schedule maintenance, and identify potential issues before they result in costly breakdowns. These systems generate valuable data that enables optimization of routing, load management, and operational strategies. The predictive analytics capabilities help establish maintenance schedules based on actual operating conditions rather than fixed intervals, improving reliability while reducing unnecessary service costs.

Emission Control Technologies

The evolution of emission control systems has transformed diesel engine design, incorporating multiple technologies that work synergistically to achieve exceptional environmental compliance. Selective catalytic reduction systems utilize diesel exhaust fluid to convert harmful nitrogen oxides into harmless nitrogen and water vapor. Diesel particulate filters capture and burn soot particles, ensuring clean exhaust while maintaining engine performance. These systems operate seamlessly in the background, requiring minimal operator intervention while delivering consistent emission reductions.

Advanced aftertreatment systems have been engineered to complement engine performance rather than compromise it. The integration of variable geometry turbochargers and high-pressure fuel injection systems optimizes combustion efficiency, reducing the formation of pollutants at the source. This comprehensive approach to emission control ensures compliance with current and anticipated future regulations while maintaining the power and reliability expected from professional-grade diesel engines. The result is a cummins engine that delivers clean operation without sacrificing the performance characteristics that define successful commercial applications.

Maintenance and Service Considerations

Preventive Maintenance Programs

Establishing comprehensive preventive maintenance programs forms the foundation of successful engine operation, significantly extending service life while minimizing unexpected failures. Regular oil analysis provides valuable insights into engine condition, identifying wear patterns and contamination issues before they progress to costly repairs. Scheduled filter replacements, coolant system maintenance, and fuel system servicing ensure optimal performance while protecting critical components from premature wear. Professional maintenance programs typically result in lower total operating costs and improved equipment availability.

The implementation of condition-based maintenance strategies leverages advanced diagnostic capabilities to optimize service intervals based on actual operating conditions. This approach moves beyond fixed schedules to focus on component condition and performance trends, enabling more efficient use of maintenance resources. Modern engines provide extensive diagnostic information that helps technicians identify developing issues and plan corrective actions during scheduled maintenance windows. This proactive approach minimizes emergency repairs and reduces the likelihood of catastrophic failures.

Parts Availability and Service Support

Comprehensive parts availability ensures minimal downtime when maintenance or repairs become necessary, supporting continuous operation in demanding applications. Extensive dealer networks provide local access to genuine components and factory-trained service technicians. The availability of remanufactured components offers cost-effective alternatives for major repairs while maintaining original equipment performance standards. Strategic parts inventory management helps operators balance carrying costs with availability requirements, ensuring critical components are accessible when needed.

Factory-trained service technicians bring specialized knowledge and diagnostic equipment that ensures proper repair procedures and component installation. Access to technical support resources, including service literature and troubleshooting guides, empowers maintenance teams to address issues efficiently. Warranty programs provide protection against unexpected failures while encouraging proper maintenance practices. The combination of parts availability, technical support, and warranty coverage creates a comprehensive service ecosystem that supports long-term engine reliability and operator confidence.

Operational Efficiency and Cost Management

Fuel Economy Optimization

Fuel efficiency represents a critical factor in engine selection, directly impacting operational costs and environmental performance. Advanced combustion systems optimize fuel delivery and timing to maximize energy extraction from each gallon of diesel fuel. Variable geometry turbochargers adjust boost pressure to match load requirements, improving efficiency across the operating range. High-pressure fuel injection systems enable precise control of combustion processes, reducing fuel consumption while maintaining power output.

Engine management systems continuously optimize operating parameters to achieve maximum fuel efficiency while protecting critical components. Load-based power management adjusts engine output to match application requirements, preventing unnecessary fuel consumption during light-duty operation. Idle management systems reduce fuel waste during extended periods of non-productive operation. These integrated efficiency technologies can result in significant fuel savings over the engine's service life, improving overall operational economics while reducing environmental impact.

Total Cost of Ownership Analysis

Evaluating total cost of ownership requires consideration of initial purchase price, fuel costs, maintenance expenses, and residual value over the engine's expected service life. Initial cost differences between engine options may be offset by superior fuel efficiency, extended service intervals, or improved reliability. Financing options and warranty coverage affect the overall financial impact of engine selection decisions. Comprehensive cost analysis helps identify the most economical solution for specific applications and operating profiles.

Resale value considerations become important factors for operators who regularly update their equipment fleets. Engines with strong reputations for reliability and durability typically maintain higher residual values, offsetting higher initial costs. Market acceptance and parts availability influence long-term value retention. The total cost of ownership analysis should account for these factors to provide an accurate comparison of engine options and support informed purchasing decisions that optimize long-term financial performance.

FAQ

What factors should be considered when selecting an engine for heavy-duty applications

Engine selection for heavy-duty applications requires careful evaluation of power requirements, duty cycle, operating environment, and maintenance capabilities. Consider the maximum power output needed for peak performance requirements while ensuring adequate reserve capacity for challenging conditions. Evaluate the engine's duty cycle rating to ensure compatibility with intended operating patterns. Environmental factors such as altitude, temperature extremes, and dust exposure influence engine selection and may require specific features or modifications.

How do modern emission control systems affect engine performance and maintenance

Contemporary emission control systems are designed to operate transparently while maintaining engine performance and reliability. Selective catalytic reduction and diesel particulate filter systems require periodic maintenance but generally operate without operator intervention. These systems may slightly increase fuel consumption but are offset by improved combustion efficiency. Proper maintenance of emission control systems is essential for continued compliance and optimal engine performance.

What maintenance practices extend engine service life

Regular oil changes using manufacturer-specified lubricants form the foundation of effective engine maintenance. Scheduled filter replacements for fuel, oil, and air systems prevent contamination-related damage. Coolant system maintenance prevents overheating and corrosion issues. Following manufacturer-recommended service intervals and using genuine or approved replacement parts ensures optimal performance and warranty compliance. Regular inspections and prompt attention to developing issues prevent minor problems from becoming major repairs.

How do electronic control systems improve engine operation

Electronic engine management systems optimize performance by continuously monitoring and adjusting operating parameters based on load conditions and environmental factors. These systems provide real-time diagnostics that enable early identification of developing issues before they result in failures. Integration with fleet management systems allows remote monitoring and data collection for improved operational planning. Electronic controls enable features like idle management, cruise control, and power take-off control that enhance operational efficiency and reduce operator fatigue.