The agricultural and construction industries rely heavily on dependable power solutions, and Kubota has established itself as a leading manufacturer of high-performance diesel engines. Whether you're operating agricultural machinery, construction equipment, or industrial generators, selecting the right kubota engine can significantly impact your operational efficiency and long-term costs. This comprehensive guide examines the top kubota engine models available in 2025, helping you make informed decisions based on performance specifications, applications, and reliability factors.

Modern kubota engine technology incorporates advanced fuel injection systems, enhanced emission controls, and improved durability features that meet stringent environmental regulations while delivering exceptional power output. Understanding the various engine series and their specific characteristics enables equipment operators to optimize their machinery performance and reduce operational downtime.

Kubota Engine Series Overview

V-Series High Performance Engines

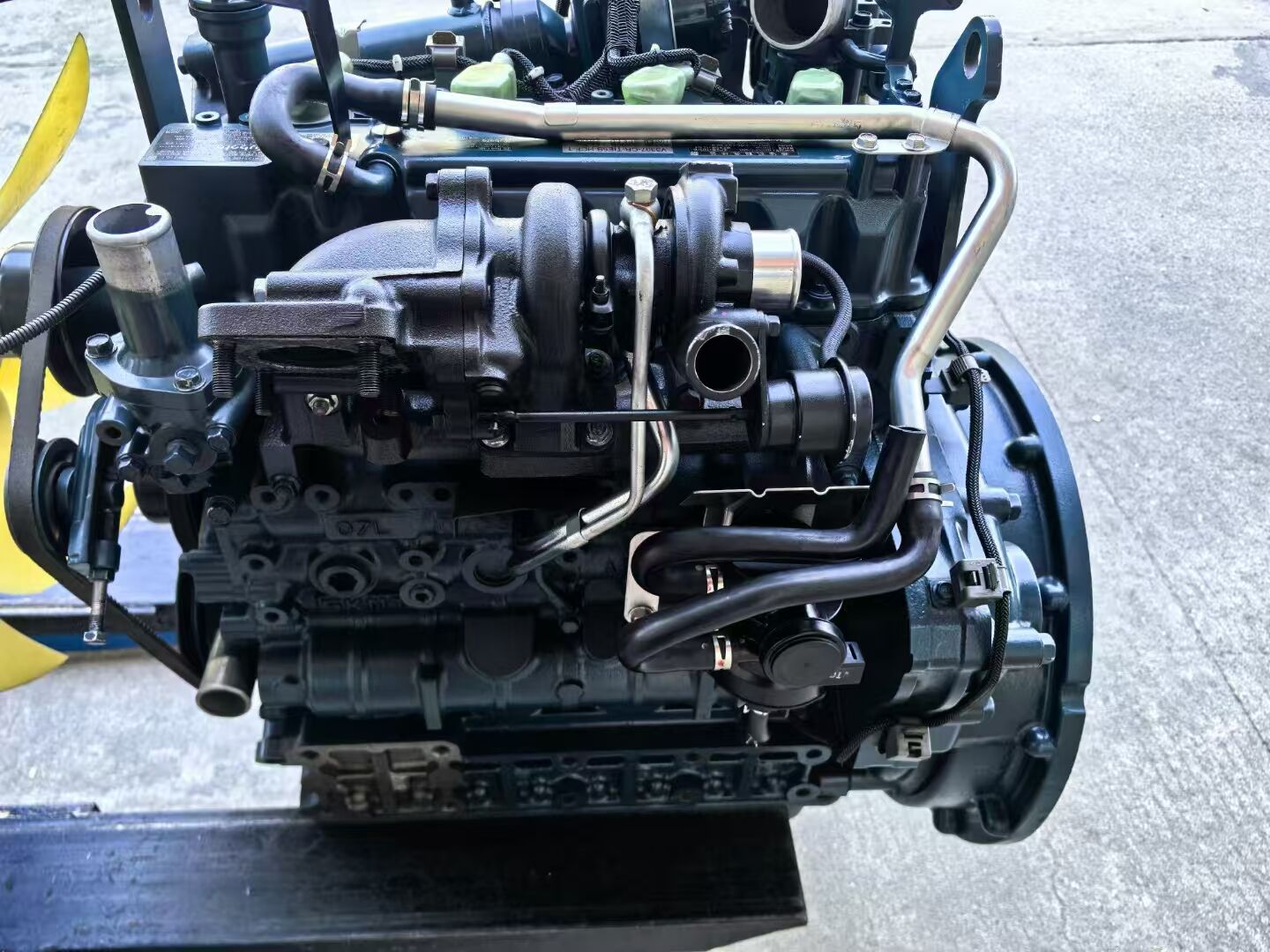

The V-Series represents Kubota's premium kubota engine lineup, featuring sophisticated turbocharging and intercooling systems designed for heavy-duty applications. These engines deliver exceptional power density while maintaining fuel efficiency standards that meet modern operational demands. The V3800 and V2403 models within this series offer displacement ranges from 2.4 to 3.8 liters, providing versatile power solutions for various industrial applications.

Advanced common rail fuel injection technology in V-Series engines ensures precise fuel delivery timing, resulting in improved combustion efficiency and reduced emissions. The robust construction includes reinforced cylinder blocks and enhanced bearing systems that withstand demanding operational conditions while maintaining consistent performance over extended service intervals.

D-Series Compact Power Solutions

The D-Series kubota engine family focuses on compact applications requiring reliable power in space-constrained environments. These engines feature displacement ranges from 0.5 to 2.2 liters, making them ideal for small agricultural equipment, compact construction machinery, and portable generators. The D1105 and D1703 models demonstrate exceptional fuel economy while delivering sufficient torque for demanding applications.

Innovative design features in D-Series engines include lightweight aluminum construction components and optimized cooling systems that maintain consistent operating temperatures. The simplified maintenance requirements and extended service intervals make these engines particularly attractive for operators seeking cost-effective power solutions with minimal downtime requirements.

Performance Specifications and Applications

Power Output and Torque Characteristics

Understanding power output specifications is crucial when selecting an appropriate kubota engine for specific applications. The power ratings range from 15 horsepower in compact D-Series models to over 140 horsepower in larger V-Series configurations. Torque characteristics vary significantly between engine series, with V-Series engines providing higher peak torque at lower RPM ranges, making them suitable for heavy-duty applications requiring substantial pulling power.

The torque curve profiles of different kubota engine models determine their suitability for various applications. Agricultural tractors benefit from engines with broad torque bands that maintain power across varying load conditions, while construction equipment requires peak torque availability at specific operating ranges for optimal performance during demanding tasks.

Fuel Efficiency and Operating Costs

Modern kubota engine designs prioritize fuel efficiency without compromising performance capabilities. Advanced fuel injection systems and optimized combustion chamber designs contribute to reduced fuel consumption rates across all operating conditions. The V-Series engines achieve fuel consumption rates as low as 0.32 pounds per horsepower-hour, while D-Series models maintain similar efficiency levels despite their compact configurations.

Operating cost analysis must consider factors beyond initial fuel consumption, including maintenance requirements, parts availability, and service intervals. Kubota engines typically feature extended oil change intervals and robust component designs that minimize maintenance frequency, resulting in lower total cost of ownership compared to competitive alternatives.

Industrial Applications and Equipment Compatibility

Agricultural Machinery Integration

Agricultural applications demand kubota engine solutions that withstand harsh environmental conditions while providing consistent power delivery. Tractors, combines, and other farming equipment benefit from engines with excellent low-end torque characteristics and reliable starting capabilities in extreme weather conditions. The V3307 and V3800 models excel in medium to large agricultural machinery applications, offering the power density required for modern precision farming operations.

Compatibility with advanced agricultural technologies, including GPS guidance systems and automated implement controls, requires engines with stable electrical output and minimal electromagnetic interference. Kubota engines incorporate sophisticated alternator systems and electrical shielding that ensure compatibility with sensitive electronic equipment commonly found in contemporary agricultural machinery.

Construction Equipment Applications

Construction equipment applications require kubota engine solutions capable of handling variable load conditions and extended operating periods. Excavators, bulldozers, and other earth-moving equipment benefit from engines with responsive throttle characteristics and robust cooling systems that maintain performance in dusty, high-temperature environments. The durability requirements for construction applications necessitate engines with reinforced components and enhanced filtration systems.

The integration of kubota engine technology in construction equipment includes considerations for hydraulic system compatibility and power take-off requirements. Modern construction machinery relies on precise hydraulic control systems that demand consistent engine speed regulation and rapid throttle response capabilities.

Maintenance Requirements and Service Considerations

Routine Maintenance Procedures

Proper maintenance procedures significantly impact the longevity and performance of any kubota engine installation. Regular oil changes using manufacturer-specified lubricants ensure optimal bearing protection and internal component lubrication. The recommended service intervals vary between engine series, with most models requiring oil changes every 250 to 500 operating hours depending on application severity and environmental conditions.

Air filtration system maintenance represents a critical aspect of kubota engine care, particularly in dusty agricultural or construction environments. Regular filter inspections and replacements prevent contamination-related damage to internal engine components while maintaining optimal air flow rates for efficient combustion processes.

Parts Availability and Service Network

The extensive Kubota dealer network ensures reliable parts availability and technical support for all kubota engine models worldwide. Genuine replacement parts maintain original equipment specifications and performance characteristics, while aftermarket alternatives may compromise reliability or void warranty coverage. The comprehensive parts inventory includes everything from routine maintenance items to major component assemblies.

Technical support services provided by authorized Kubota dealers include diagnostic capabilities, repair procedures, and performance optimization recommendations. The availability of factory-trained technicians ensures proper service procedures and maintains warranty compliance throughout the engine's operational life.

Environmental Compliance and Emission Standards

Tier 4 Final Emission Standards

Current kubota engine models comply with stringent Tier 4 Final emission standards through advanced after-treatment systems and optimized combustion technologies. These regulations require significant reductions in nitrogen oxide and particulate matter emissions compared to previous standards. The implementation of diesel particulate filters and selective catalytic reduction systems ensures compliance while maintaining performance capabilities.

The integration of emission control systems adds complexity to kubota engine installations but provides environmental benefits and regulatory compliance assurance. Operators must understand the maintenance requirements for after-treatment components, including diesel exhaust fluid replenishment and filter regeneration procedures that maintain emission compliance throughout the engine's service life.

Future Emission Regulations

Anticipated future emission regulations will likely impose even stricter standards on diesel engine manufacturers, driving continued innovation in kubota engine technology. Advanced combustion strategies, alternative fuel compatibility, and hybrid power systems represent potential development directions for future engine generations. Understanding regulatory trends helps equipment purchasers make informed decisions about long-term asset viability.

The evolution toward sustainable power solutions influences kubota engine development priorities, with increased emphasis on biodiesel compatibility and reduced carbon footprint technologies. These developments ensure continued relevance of diesel engine technology in environmentally conscious markets while maintaining the performance characteristics that define modern industrial applications.

Selection Criteria and Decision Factors

Application-Specific Requirements

Selecting the appropriate kubota engine requires careful analysis of specific application requirements, including power demands, operating environment, and duty cycle characteristics. Agricultural applications typically prioritize fuel efficiency and low-end torque, while construction equipment emphasizes durability and responsive power delivery. Understanding these requirements ensures optimal engine selection for intended applications.

Environmental factors significantly influence engine selection decisions, with considerations for altitude, temperature extremes, and contamination exposure affecting performance and longevity. High-altitude applications may require naturally aspirated engines or modified turbocharging systems, while extreme temperature conditions necessitate enhanced cooling or cold-start capabilities.

Total Cost of Ownership Analysis

Comprehensive total cost of ownership analysis considers initial purchase price, fuel consumption, maintenance requirements, and residual value factors. While premium kubota engine models may command higher initial costs, their superior fuel efficiency and extended service intervals often result in lower lifetime operating expenses. This analysis becomes particularly important for high-utilization applications where operational costs dominate total ownership expenses.

Financing options and warranty coverage also influence the total cost equation, with extended warranty programs providing protection against unexpected repair costs. The reputation for reliability and extensive dealer support network adds value beyond basic performance specifications, contributing to higher resale values and improved asset utilization rates.

FAQ

What factors should I consider when choosing between different kubota engine series?

When selecting between kubota engine series, consider your specific power requirements, operating environment, and duty cycle demands. V-Series engines offer higher power output and advanced features for demanding applications, while D-Series models provide compact, fuel-efficient solutions for lighter-duty uses. Evaluate factors such as required horsepower, torque characteristics, space constraints, fuel efficiency priorities, and maintenance accessibility to determine the most suitable series for your application.

How do kubota engines compare to competitive brands in terms of reliability and performance?

Kubota engines consistently rank among the most reliable diesel engines in the industrial market, with proven track records in agricultural and construction applications worldwide. Their robust construction, advanced fuel injection systems, and comprehensive dealer support network contribute to exceptional reliability ratings. Performance characteristics typically match or exceed competitive alternatives while offering superior fuel efficiency and lower emission levels. The extensive parts availability and factory support further enhance their competitive advantage.

What maintenance procedures are critical for maximizing kubota engine longevity?

Critical maintenance procedures include regular oil changes using manufacturer-specified lubricants, air filter replacement based on operating conditions, coolant system maintenance, and fuel filter replacement at recommended intervals. Additionally, maintaining proper belt tension, monitoring emission system components, and following proper warm-up and cool-down procedures significantly impact engine longevity. Regular inspections of mounting systems, electrical connections, and cooling system components help identify potential issues before they become major problems.

Are kubota engines compatible with biodiesel and alternative fuel sources?

Most modern kubota engines support biodiesel blends up to B20 (20% biodiesel, 80% petroleum diesel) without modifications, though specific compatibility varies by model and application. Higher biodiesel concentrations may require fuel system modifications and more frequent filter changes due to biodiesel's solvent properties. Always consult manufacturer specifications and warranty guidelines before using alternative fuels, as improper fuel selection can void warranty coverage and potentially damage fuel system components.

Table of Contents

- Kubota Engine Series Overview

- Performance Specifications and Applications

- Industrial Applications and Equipment Compatibility

- Maintenance Requirements and Service Considerations

- Environmental Compliance and Emission Standards

- Selection Criteria and Decision Factors

-

FAQ

- What factors should I consider when choosing between different kubota engine series?

- How do kubota engines compare to competitive brands in terms of reliability and performance?

- What maintenance procedures are critical for maximizing kubota engine longevity?

- Are kubota engines compatible with biodiesel and alternative fuel sources?