При оценката на мощни решения за тежки натоварвания в промишлени приложения, разбирането на изчерпващите спецификации на двигателя е от първостепенно значение за постигане на оптимална производителност. Съвременната индустриална среда изисква надеждни и ефективни задвижващи системи, които осигуряват постоянни резултати в различни работни условия. Този изчерпателен наръчник разглежда ключови спецификации, показатели за производителност и технически аспекти, които дефинират високата двигателна производителност в днешните изискващи индустриални сектори.

Индустриалните оператори се нуждаят от подробни технически познания, за да вземат информирани решения относно инвестициите в силови агрегати. Спецификациите на двигателите обхващат множество критични параметри, включително работен обем, криви на въртящия момент, разход на гориво, стандарти за емисии и работни температурни диапазони. Тези фактори влияят пряко върху производителността на оборудването, оперативните разходи и дългосрочната надеждност в трудни работни условия.

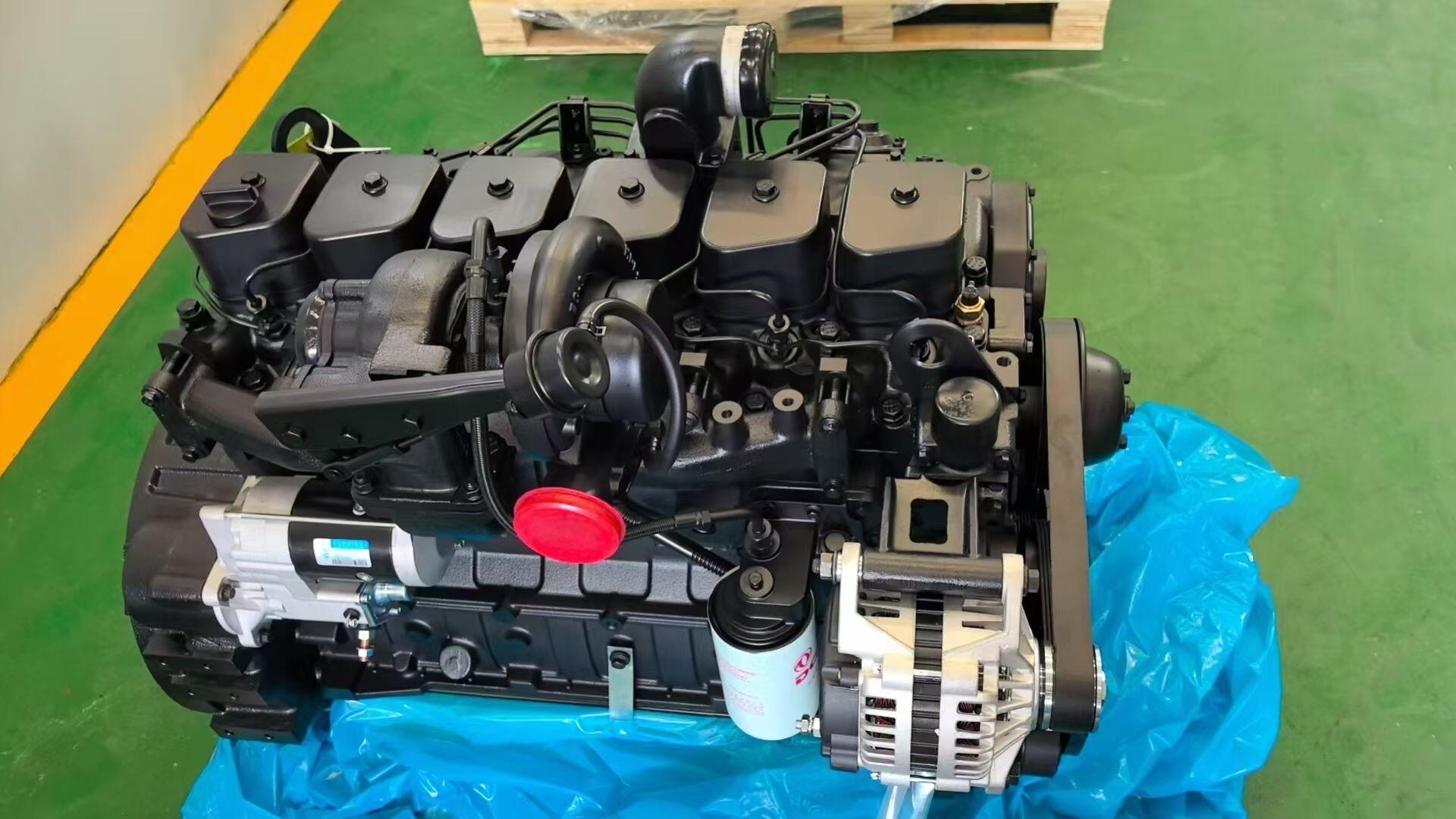

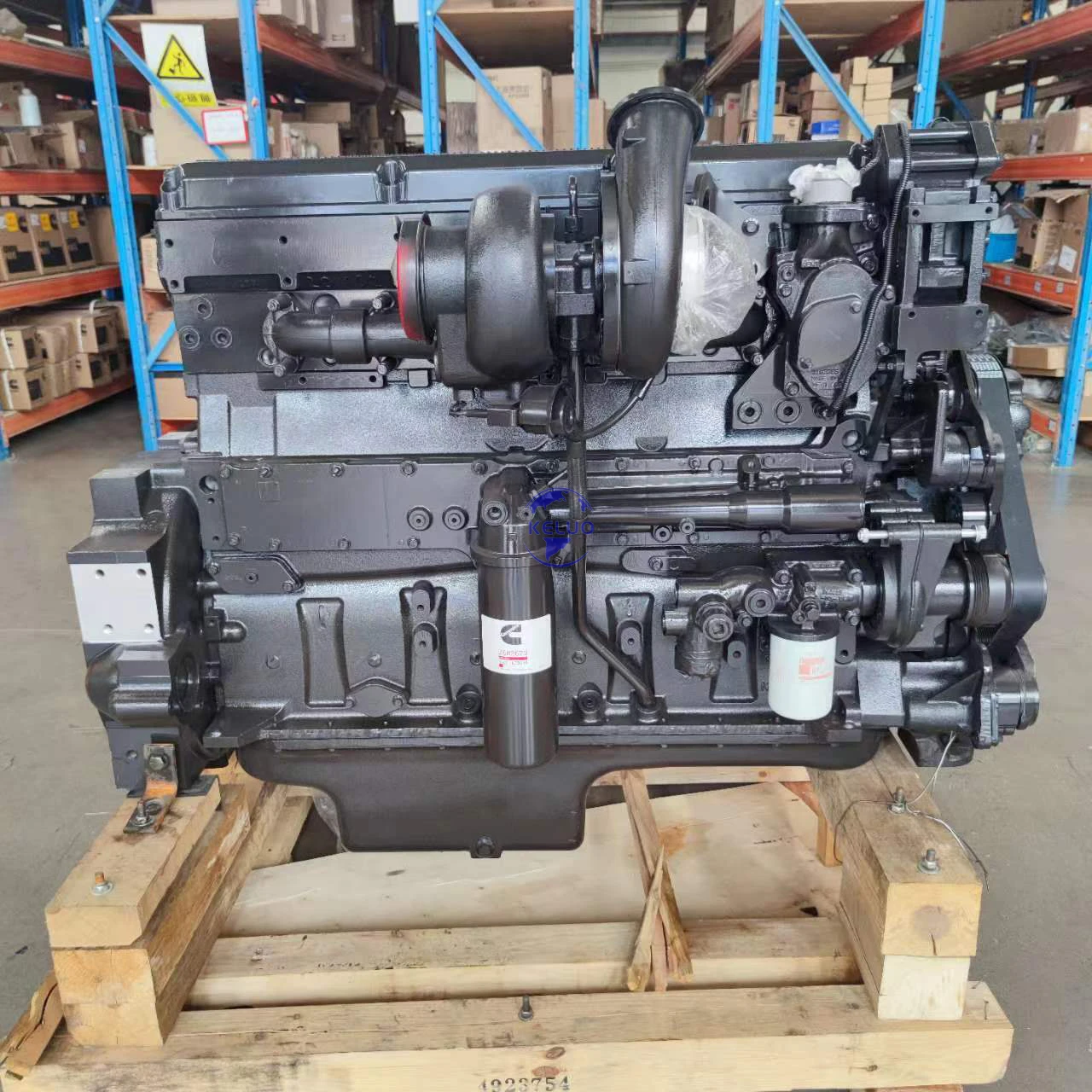

Развитието на технологията на дизеловите двигатели въведе напреднали функции, които подобряват производителността, като същевременно отговарят на строги екологични изисквания. Съвременните двигатели включват сложни системи за впръскване на гориво, технологии за турбонадуване и електронни управляващи модули, които оптимизират ефективността на горенето при различни натоварвания.

Основни спецификации на двигателя и показатели за производителност

Обем и характеристики на мощността

Обемът на двигателя представлява общия обем на всички цилиндри и е пряко свързан с потенциалните възможности за мощност. Двигатели с по-голям обем обикновено генерират по-висок въртящ момент, което ги прави подходящи за тежки приложения, изискващи значителна теглителна сила. Връзката между обема и мощността варира в зависимост от конструкцията на двигателя, системите за подаване на гориво и конфигурациите на турбоподпомагане.

Спецификациите за мощност включват както пиковата мощност в к.с., така и номиналните стойности за непрекъсната работа. Пиковата мощност в к.с. показва максималната краткосрочна производителност, докато номиналните стойности за непрекъсната работа представляват устойчиви нива на мощност за продължителни операции. Разбирането на тази разлика помага на операторите да избират подходящи двигатели за конкретни режими на работа и експлоатационни изисквания.

Характеристиките на въртящия момент определят способността на двигателя да генерира въртяща сила в различните диапазони на оборотите. Максималният въртящ момент обикновено се достига при по-ниски обороти при дизеловите двигатели, което осигурява отлична теглителна сила при ниски обороти за приложения с тежка техника. Формата на кривата на въртящия момент влияе на ускорението и общата експлоатационна ефективност.

Технологии на горивната система и ефективност

Съвременните системи за впръскване на гориво използват технологии с общ релсов висок налягане, за да постигнат прецизна дозировка на горивото и контрол върху момента на впръскване. Тези системи поддържат множество впръсквания за един цикъл на горене, оптимизирайки разпръскването на горивото и ефективността на горенето, като едновременно намаляват емисиите и нивата на шум.

Електронните системи за управление на горивото следят експлоатационните параметри в реално време и нагласят подаването на гориво според натоварването, атмосферните условия и командите на оператора. Този интелигентен контрол подобрява икономичността на горивото, като запазва оптималната производителност при различни експлоатационни условия.

Спецификациите за разход на гориво обикновено включват показатели при различни нива на натоварване, като предоставят на операторите реалистични очаквания за експлоатационните разходи. Тези показатели вземат предвид фактори като обороти на двигателя, коефициент на натоварване, околна температура и височина над морското равнище, които влияят върху действителните нива на разход на гориво.

Напреднали инженерни характеристики и технологии

Турбонадуване и системи за управление на въздуха

Технологията за турбонадуване значително подобрява производителността на двигателя, като увеличава плътността на въздуха, постъпващ в камерите за горене. Турбокомпресорите с променлива геометрия регулират ъглите на лопатките, за да оптимизират въздушния поток при различни обороти на двигателя, подобрявайки отговорните характеристики и ефективността в целия работен диапазон.

Системите за междинно охлаждане намаляват температурата на компресирания въздух, което допълнително увеличава плътността му и позволява по-висока мощност, като същевременно запазва температурите на горенето в допустимите граници. Напреднали системи за управление на въздуха синхронизират работата на турбокомпресора с рециркулацията на изгорелите газове, за да оптимизират както производителността, така и контрола на емисиите.

Системите за филтриране на въздуха предпазват вътрешните компоненти от замърсители, като осигуряват достатъчен въздушен поток за оптимално горене. Високопроизводителни въздушни филтри с индикатори за задръстване помагат на операторите да поддържат максимална производителност, като гарантират навременни интервали за поддръжка.

Електронни системи за управление и наблюдение

Сложни електронни управляващи модули управляват едновременно множество функции на двигателя, включително момент на впръскване на гориво, налягане на турбокомпресора, степен на рециркулация на изгорелите газове и работата на охлаждащата система. Тези системи непрекъснато следят входните сигнали от сензори и коригират параметрите, за да осигурят оптимална производителност и да предпазят критични компоненти.

Диагностичните възможности осигуряват мониторинг в реално време на параметрите за състоянието на двигателя и предупреждават навреме за възможни проблеми, преди те да доведат до скъпоструващ простои. Напреднали системи могат да комуникират със софтуер за управление на парка, за да проследяват тенденциите в производителността и автоматично да планират превантивно поддържане.

Програмируемите настройки на мощността позволяват на операторите да настройват характеристиките на двигателя за конкретни приложения, като балансират изходната мощност със захранвателната ефективност въз основа на експлоатационните изисквания. Тези функции увеличават универсалността, като едновременно оптимизират експлоатационните разходи.

Технологии за контрол на емисиите и съответствие

Системи за по-нататъшна обработка на отработените газове

Съвременните двигатели включват изчерпателни системи за по-нататъшна обработка на отработените газове, за да отговарят на строгите разпоредби за емисии, като същевременно запазват стандартите за производителност. Филтрите за прахови частици от дизелови газове улавят и изгарят натрупаните сажди, намалявайки емисиите на прахови частици до допустими нива.

Системите за селективно каталитично редуциране впръскват течност за дизелови изпускателни газове в изпускателния поток, за да превърнат оксидите на азота в безвреден азот и водна пара. Тези системи изискват периодично попълване на течността, но значително намаляват вредните емисии, без да компрометират работата на двигателя.

Системите за рециркулация на изгорелите газове понижават температурите на горенето, като рециркулират част от изгорелите газове обратно във впускната система. Този процес намалява образуването на оксиди на азота, като запазва допустимите нива на производителност при различни работни условия.

Стандарти за съответствие и сертифициране

Стандартите за съответствие по отношение на емисиите се различават в зависимост от географския регион и вида приложение и изискват двигателите да отговарят на определени сертификационни изисквания. Стандартите „Ниво 4 крайно“ представляват най-строгите изисквания за дизелови двигатели за внепътно използване и задължават от значително намаляване на отделените частици и емисиите на оксиди на азота.

Сертификационните процеси включват обширни изпитвания при контролирани условия, за да се потвърдят нивата на емисии и характеристиките за издръжливост. Производителите трябва да докажат съответствие в целия експлоатационен диапазон и да осигурят гаранционно покритие за компонентите за контрол на емисиите.

Непрекъснатото наблюдение на съответствието гарантира, че двигателят запазва стандарта за емисии през целия си експлоатационен живот. Редовното тестване и поддържане на системите за контрол на емисиите помага на операторите да избягват санкции, като едновременно допринасят за постигането на целите за опазване на околната среда.

Експлоатационни съображения и приложения

Изисквания за натоварване и избор на двигател

Различните приложения изискват двигатели, оптимизирани за специфични режими на работа, вариращи от прекъсвиста лека експлоатация до непрекъсната тежка служба. Разбирането на коефициентите на натоварване, работните часове и околните условия помага да се определят подходящите спецификации на двигателя за надеждна дългосрочна производителност.

Строителната техника обикновено изисква двигатели с отлично нискообортово въртящо усилие и чувствителни дроселни характеристики, за да може ефективно да се справя с променливи натоварвания. При минните приложения се изискват двигатели, способни на непрекъснато високопроизводително функциониране в сурови околните условия при минимални изисквания за поддръжка.

При морските и земесмучителни приложения се получава полза от двигатели, проектирани за непрекъснато работене с усъвършенствани системи за охлаждане и компоненти, устойчиви на корозия. Двигателите двигател Cummins конфигурациите за тези приложения често включват специализирани характеристики за морската среда и удължени интервали за поддръжка.

Изисквания за поддръжка и Услуга Интервали

Графиците за превантивна поддръжка директно влияят на надеждността на двигателя и експлоатационните разходи през целия експлоатационен живот на оборудването. Редовните смяны на масло, замяна на филтри и инспекции на системата помагат да се поддържа пиковата производителност и да се идентифицират потенциални проблеми, преди те да доведат до скъпоструващи повреди.

Разширените интервали за обслужване намаляват разходите за поддръжка и простоите на оборудването, особено важно при приложения, при които достъпът е ограничен. Системи за филтриране с голяма капацитетност и синтетични смазки позволяват по-дълги интервали между обслужванията, без да се компрометира защитата или производителността.

Системите за мониторинг на състоянието следят ключови параметри като качество на маслото, температура на охлаждащата течност и нива на вибрации, за да оптимизират моментите на поддръжка въз основа на реалните работни условия, а не на фиксирани графици. Този подход максимизира наличността на оборудването, като едновременно минимизира разходите за поддръжка.

Оптимизация на производителността и повишаване на ефективността

Настройки на работни параметри

Оптимизирането на двигателната производителност изисква разбиране на взаимовръзката между различните работни параметри и тяхното въздействие върху разхода на гориво, мощността и продължителността на живот на компонентите. Правилното управление на дросела, разпределението на натоварването и изборът на работна скорост значително влияят върху общата ефективност и експлоатационните разходи.

Околни фактори като надморска височина, температура и влажност влияят на двигателните характеристики. Работата на висока надморска височина намалява плътността на въздуха, което изисква корекции в подаването на гориво и работата на турбокомпресора, за да се запази мощността. При работа при ниски температури може да се наложи използването на предгряващи устройства за двигателя и модифицирано гориво, за надеждно стартиране и функциониране.

Стратегиите за управление на натоварването помагат за оптимизиране на разхода на гориво, като същевременно се осигурява необходимата производителност. Работата на двигатели при 75-85% от номиналната им мощност обикновено осигурява най-добрия баланс между икономичност и достъпна мощност при променливи натоварвания.

Интеграция на технологии и управление на парка

Съвременните системи за управление на паркове се интегрират с модулите за контрол на двигателя, за да осигурят всеобхватен мониторинг и възможности за оптимизация. Събирането на данни в реално време позволява на операторите да идентифицират неефективности, да проследяват моделите на разход на гориво и да оптимизират графиките за поддръжка въз основа на действителните модели на използване.

Телематичните системи осигуряват възможности за дистанционен мониторинг, които позволяват на мениджърите на паркове да следят производителността на двигателя, местоположението и експлоатационното състояние от централизирани контролни центрове. Тази свързаност осигурява възможност за планиране на превантивно поддържане и бърз отговор при експлоатационни проблеми.

Аналитиката за производителност помага да се идентифицират тенденции и възможности за оптимизация в целия парк. Сравнителният анализ между подобни единици, работещи в различни условия, разкрива най-добри практики и възможности за обучение на операторите.

ЧЗВ

Какви фактори определят подходящия обем на двигателя за конкретни приложения

Изборът на обем на двигателя зависи от изискванията за мощност, характеристиките на работния цикъл, целите за икономичност на горивото и ограниченията в пространството. Двигателите с по-голям обем обикновено осигуряват по-висок въртящ момент за тежки натоварвания, докато по-малките могат да предложат по-добра икономия на гориво при по-леки натоварвания. При избора на обем имайте предвид пиковите нужди от мощност, постоянните работни изисквания и наличното монтажно пространство.

Как системите с турбоподсилване подобряват производителността и ефективността на двигателя

Турбоподсилването увеличава плътността на въздуха, постъпващ в камерата за горене, което позволява по-ефективното изгаряне на повече гориво и генериране на по-висока мощност от същия обем. Тази технология подобрява съотношението мощност-тегло, повишава икономичността на горивото при натоварване и осигурява по-добра производителност на високи надморски височини, където естествената плътност на въздуха е намалена.

Какви практики по поддръжка оптимизират дълголетието и производителността на двигателя

Редовната смяна на масло и филтър с използване на течности, посочени от производителя, осигурява правилно смазване и контрол на замърсяванията. Поддържането на въздушния филтър гарантира достатъчен приток на въздух за оптимално горене, докато обслужването на охлаждащата система предотвратява повреди от прегряване. Спазването на предписаните интервали за сервизно обслужване и наблюдението на ключови параметри чрез диагностични системи помага да се идентифицират проблеми, преди да доведат до сериозни повреди.

Как системите за контрол на емисиите влияят на работата на двигателя и изискванията за поддръжка

Съвременните системи за контрол на емисиите изискват попълване на течност за дизелови изпускателни газове, периодични цикли на регенерация за филтри за частици и специализирани процедури за поддръжка. Тези системи могат леко да намалят разхода на гориво, но значително намаляват вредните емисии. Правилната поддръжка на компонентите за контрол на емисиите осигурява спазване на разпоредбите, запазвайки ефективността на двигателя и избягване на скъпи ремонти.

Съдържание

- Основни спецификации на двигателя и показатели за производителност

- Напреднали инженерни характеристики и технологии

- Технологии за контрол на емисиите и съответствие

- Експлоатационни съображения и приложения

- Оптимизация на производителността и повишаване на ефективността

-

ЧЗВ

- Какви фактори определят подходящия обем на двигателя за конкретни приложения

- Как системите с турбоподсилване подобряват производителността и ефективността на двигателя

- Какви практики по поддръжка оптимизират дълголетието и производителността на двигателя

- Как системите за контрол на емисиите влияят на работата на двигателя и изискванията за поддръжка