Marine vessels operating in demanding maritime environments require sophisticated engine systems that deliver reliable performance while maintaining operational efficiency. The integration of advanced cooling technologies has revolutionized marine propulsion, with watercooled turbocharger systems emerging as a critical component for modern vessel operations. These innovative systems combine the power enhancement benefits of turbocharging with superior thermal management, resulting in quieter operation and improved overall efficiency across diverse marine applications.

Understanding Watercooled Turbocharger Technology

Core Components and Design Principles

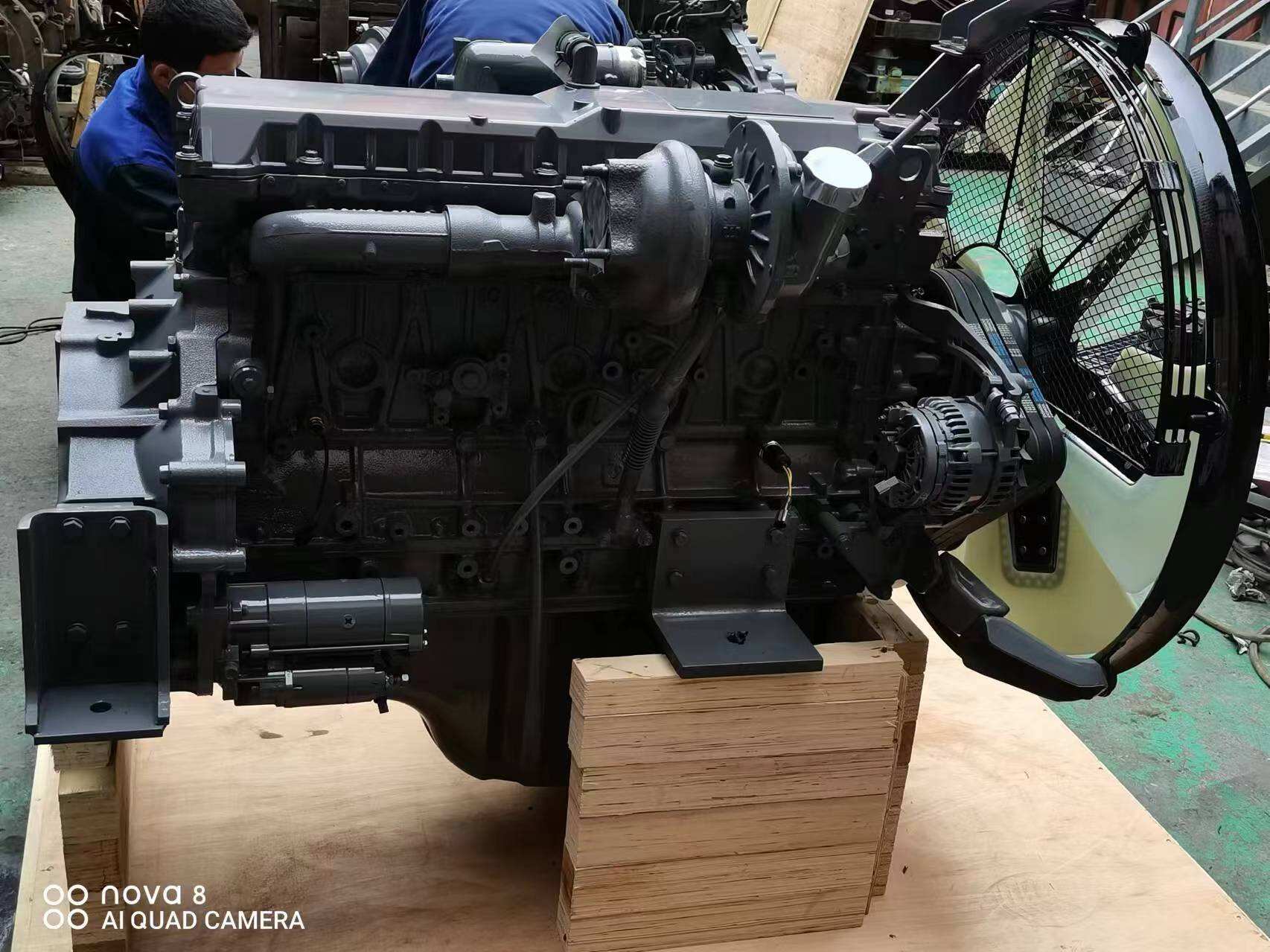

A watercooled turbocharger represents an advanced evolution of traditional turbocharging technology, incorporating integrated cooling circuits that manage thermal loads more effectively. The system utilizes engine coolant circulation through dedicated passages within the turbocharger housing, maintaining optimal operating temperatures even under extreme load conditions. This design approach addresses the inherent heat generation challenges associated with turbocharging while preserving the performance benefits that make turbocharged engines essential for marine applications.

The cooling system architecture typically includes specialized coolant passages integrated into both the compressor and turbine housings. These passages allow engine coolant to flow continuously through the turbocharger assembly, absorbing excess heat generated during the compression and expansion processes. The result is a more thermally stable system that can maintain consistent performance characteristics across varying operational conditions.

Thermal Management Benefits

Effective thermal management through watercooled turbocharger systems provides significant advantages over air-cooled alternatives. The continuous circulation of coolant helps maintain bearing temperatures within optimal ranges, reducing thermal stress on critical components and extending overall system longevity. This thermal stability is particularly crucial in marine environments where ambient temperatures and operational demands can vary significantly.

The improved heat dissipation capabilities of a watercooled turbocharger also enable more aggressive tuning parameters without compromising reliability. Engineers can optimize boost pressure levels and compression ratios more effectively when thermal constraints are properly managed, resulting in enhanced power output and fuel efficiency characteristics that benefit vessel operators through reduced operational costs and improved performance metrics.

Noise Reduction Mechanisms

Acoustic Benefits of Water Cooling

One of the most noticeable advantages of watercooled turbocharger systems is their contribution to reduced operational noise levels. The integration of cooling circuits creates additional mass and thermal stability within the turbocharger assembly, which helps dampen vibrations and reduce the high-frequency noise typically associated with turbocharger operation. This acoustic improvement is particularly valuable in marine applications where crew comfort and regulatory compliance regarding noise emissions are important considerations.

The thermal stability provided by water cooling also helps maintain more consistent clearances between rotating and stationary components within the turbocharger. This dimensional stability reduces the potential for noise-generating contact or excessive clearances that can create unwanted acoustic emissions. The result is a smoother, quieter operation that enhances the overall vessel environment.

Vibration Control and Structural Benefits

Watercooled turbocharger systems contribute to vibration reduction through improved thermal balance and reduced thermal cycling effects. The consistent cooling provided by the water circulation system helps maintain more uniform temperatures across the turbocharger assembly, reducing thermal expansion and contraction cycles that can generate mechanical stress and associated vibrations.

The additional mass of the cooling system components also provides natural vibration damping characteristics. This increased thermal mass helps absorb and dissipate vibrational energy that would otherwise be transmitted through the engine mounting system to the vessel structure. The cumulative effect is a reduction in both airborne and structure-borne noise transmission throughout the vessel.

Efficiency Improvements and Performance Optimization

Enhanced Combustion Characteristics

The superior thermal management capabilities of watercooled turbocharger systems directly contribute to improved combustion efficiency through better charge air density control. By maintaining optimal compressor temperatures, these systems can deliver more consistent charge air density to the engine cylinders, resulting in more complete combustion and improved fuel efficiency characteristics.

The thermal stability also enables more precise control over boost pressure delivery across varying operational conditions. This consistency helps maintain optimal air-fuel ratios regardless of ambient temperature fluctuations or load variations, contributing to cleaner combustion and reduced emissions output. These improvements translate directly to operational cost savings and environmental compliance benefits for vessel operators.

Power Output Optimization

Watercooled turbocharger technology enables marine engines to maintain higher sustained power output levels without experiencing thermal limitations that might restrict performance. The effective heat removal capabilities allow for more aggressive boost pressure settings and higher compression ratios, directly translating to increased power density from the same engine displacement.

This power optimization capability is particularly valuable in marine applications where space and weight constraints limit engine size options. A watercooled turbocharger system allows smaller displacement engines to deliver power levels traditionally requiring larger, naturally aspirated alternatives, providing vessel designers with greater flexibility in power plant selection and installation configurations.

Marine Application Advantages

Operational Reliability in Maritime Environments

Marine environments present unique challenges for engine cooling systems, including saltwater corrosion concerns, temperature variations, and extended operation periods without maintenance opportunities. Watercooled turbocharger systems address these challenges through robust design approaches that integrate seamlessly with existing engine cooling circuits, providing reliable operation under demanding maritime conditions.

The integration with engine cooling systems also provides inherent redundancy benefits, as the turbocharger cooling circuit typically shares components with the main engine cooling system. This shared infrastructure approach reduces complexity while providing improved reliability compared to independent cooling systems that might require additional pumps, heat exchangers, or control systems.

Maintenance and Service Considerations

Modern watercooled turbocharger systems are designed with marine maintenance requirements in mind, incorporating features that facilitate routine service procedures and extend maintenance intervals. The improved thermal management reduces stress on wear components, extending bearing life and reducing the frequency of major overhaul requirements.

The integration with existing engine cooling systems also simplifies maintenance procedures, as service technicians can utilize familiar cooling system service techniques and equipment. This familiarity reduces training requirements and maintenance costs while improving service quality and reducing downtime during maintenance periods.

Technology Integration and System Compatibility

Engine Management System Integration

Contemporary watercooled turbocharger systems are designed to integrate seamlessly with advanced engine management systems, providing real-time monitoring and control capabilities that enhance overall system performance. These integration capabilities include temperature monitoring, boost pressure control, and diagnostic functions that help optimize performance while protecting system components from damage.

The diagnostic capabilities provided by integrated systems enable predictive maintenance approaches that can identify potential issues before they result in system failures. This proactive maintenance capability is particularly valuable in marine applications where unscheduled downtime can result in significant operational disruptions and costs.

Retrofit and Upgrade Possibilities

Many existing marine engine installations can benefit from watercooled turbocharger retrofits that provide performance and efficiency improvements without requiring complete engine replacement. These upgrade options enable vessel operators to modernize their power plants incrementally, improving operational characteristics while managing capital expenditure requirements.

The retrofit process typically involves integration with existing cooling system infrastructure, making the upgrade process more straightforward and cost-effective than alternatives requiring completely independent cooling circuits. This compatibility with existing systems reduces installation complexity and associated costs while providing immediate performance benefits.

Environmental and Regulatory Benefits

Emissions Reduction Capabilities

Watercooled turbocharger systems contribute to emissions reduction through improved combustion efficiency and enhanced engine optimization capabilities. The consistent charge air density and temperature control provided by these systems enable more complete combustion, reducing particulate matter and unburned hydrocarbon emissions that contribute to marine pollution.

The thermal stability also enables the use of advanced emission control strategies, including exhaust gas recirculation and selective catalytic reduction systems that require precise temperature and flow control for optimal operation. These capabilities help marine operators meet increasingly stringent environmental regulations while maintaining operational efficiency.

Fuel Efficiency and Resource Conservation

The improved efficiency characteristics provided by watercooled turbocharger systems directly contribute to reduced fuel consumption, providing both economic and environmental benefits. The consistent performance delivery enabled by effective thermal management translates to more efficient energy conversion and reduced resource consumption per unit of useful work output.

These fuel efficiency improvements are particularly significant in marine applications where fuel costs represent a substantial portion of operational expenses. The combination of improved efficiency and extended maintenance intervals provides compelling economic justification for watercooled turbocharger system adoption across diverse marine applications.

FAQ

What maintenance advantages does a watercooled turbocharger provide over air-cooled alternatives

Watercooled turbocharger systems typically require less frequent maintenance due to reduced thermal stress on internal components. The consistent cooling provided by the water circulation system helps maintain optimal bearing temperatures and reduces thermal cycling effects that can accelerate wear. This results in extended service intervals and reduced maintenance costs compared to air-cooled alternatives that experience greater temperature variations and thermal stress.

How does water cooling affect turbocharger response time and performance

While the additional thermal mass of a watercooled turbocharger system might seem to slow response time, the improved thermal stability actually enhances overall performance consistency. The system maintains more consistent operating temperatures, which helps preserve boost response characteristics across varying ambient conditions. The thermal stability also enables more aggressive tuning parameters that can improve overall performance delivery.

Can existing marine engines be retrofitted with watercooled turbocharger systems

Many marine engines can accommodate watercooled turbocharger retrofits, particularly when the existing cooling system has adequate capacity for the additional cooling load. The retrofit process typically involves integrating the turbocharger cooling circuit with existing engine cooling infrastructure, making the upgrade process more straightforward than systems requiring independent cooling circuits. Professional evaluation is recommended to ensure system compatibility and optimal performance.

What are the long-term operational cost benefits of watercooled turbocharger systems

Long-term cost benefits include reduced fuel consumption through improved efficiency, extended maintenance intervals due to reduced thermal stress, and improved component longevity. The thermal stability provided by watercooled systems also enables more consistent performance delivery, reducing the need for frequent tuning adjustments and associated service costs. These factors combine to provide compelling economic justification for the initial investment in watercooled turbocharger technology.

Table of Contents

- Understanding Watercooled Turbocharger Technology

- Noise Reduction Mechanisms

- Efficiency Improvements and Performance Optimization

- Marine Application Advantages

- Technology Integration and System Compatibility

- Environmental and Regulatory Benefits

-

FAQ

- What maintenance advantages does a watercooled turbocharger provide over air-cooled alternatives

- How does water cooling affect turbocharger response time and performance

- Can existing marine engines be retrofitted with watercooled turbocharger systems

- What are the long-term operational cost benefits of watercooled turbocharger systems