Gradbeni sektor stoji na križišču, saj se tradicionalna dizelska oprema sooča s svečjo večjim pritiskom iz novega električnega alternativ. Ta preobrazba je še posebej očitna na področju motorjev bagrov, kjer se že desetletja...

Ogledaj več

Ko pride do izpada bagra zaradi težav z motorjem, morajo upravljavci sprejeti pomembno odločitev med poskusom samostojne popravile ali pa iskanjem strokovne storitve. Ta izbira znatno vpliva na obratovalne stroške, časovne razporede projektov in opremo...

Ogledaj več

Uporabniki težke mehanizacije in vodje parkov vedo, da je ohranjanje optimalne zmogljivosti motorja bagra ključno za uspeh projekta in operativno učinkovitost. Če motor bagra doživi težave, lahko pride do dragocenega zastoja, zamud ...

Ogledaj več

Ustrezen servis industrijskih motorjev je osnova za zagotavljanje optimalne zmogljivosti, dolge življenjske dobe in ekonomičnega obratovanja v različnih aplikacijah. Dobro vzdrževana diesel motorja sestava lahko zagotovi desetletja zanesljivega delovanja, če je izpostavljena ...

Ogledaj več

Industrijska panoga napreduje s hitrim tempom, pri čemer postajajo sistemi sestave diesel motorjev vse bolj sofisticirani in učinkoviti. Ko se približujemo letu 2026, proizvajalci zahtevajo zanesljivejše, racionalnejše po porabi goriva ter okolju prijaznejše ...

Ogledaj več

Ko se težka gradbena oprema pokvari na gradbišču, se vsaka minuta izpada pretvori v izgubo produktivnosti in prihodkov. Motorji Caterpillar pogonijo milijone bagrov, buldožerjev in druge težke opreme po vsem svetu, kar naredi zanesljivo odpravljanje težav nujno za ohranjanje delovanja naprav.

Ogledaj več

Pravilno vzdrževanje motorja Caterpillar je ključnega pomena za maksimiranje zmogljivosti opreme, zmanjšanje izpadov in podaljšanje življenjske dobe. Uporabniki težke opreme in gradbene strokovnjake se zanašajo na te močne enote, da zagotavljajo zanesljivost in učinkovitost.

Ogledaj več

Kmetijska in gradbena industrija zelo zavisa od zanesljivih energetskih rešitev, Kubota pa se je uveljavila kot vodilni proizvajalec visoko zmogljivih dizelskih motorjev. Ne glede na to, ali upravljate kmetijsko opremo, gradbene stroje...

Ogledaj več

Pri ocenjevanju močnih napajalnih rešitev za industrijske aplikacije je ključnega pomena razumevanje celovitih tehničnih specifikacij motorja za optimalne rezultate zmogljivosti. Moderna industrijska pokrajina zahteva zanesljive in učinkovite pogonske sisteme, ki...

Ogledaj več

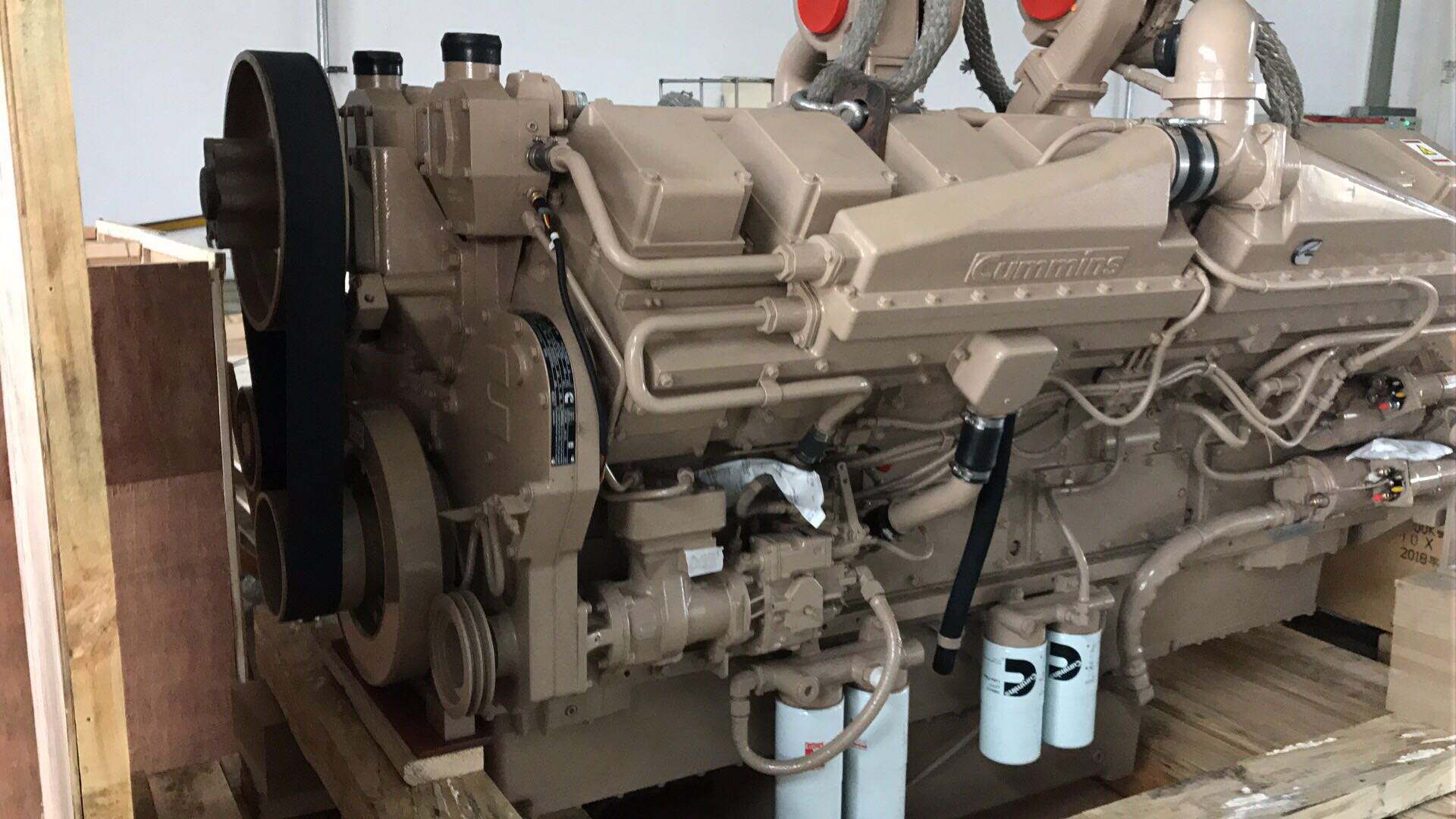

Ko gre za pogon tovornih vozil, ki zahtevajo izjemno zmogljivost in zanesljivost, le redki proizvajalci lahko tekmujejo s reputacijo in inženirskim izjemnostjo podjetja Cummins. Že desetletja flote, proizvajalci tovornih vozil in neodvisni vozniki...

Ogledaj več

Pri naložbi v težko opremo ali industrijske stroje postane razumevanje življenjske dobe in zanesljivosti vira energije ključnega pomena za uspešno delovanje. Motor cummins si je pridobil ugled merila v svetu dizelskih motorjev v...

Ogledaj več

Pravilno vzdrževanje je temelj podaljšanja življenjske dobe in zagotavljanja optimalnega delovanja vašega motorja Cummins. Ne glede na to, ali pogoni morska plovila, tovornjake ali težko mehanizacijo, ti močni dizelski motorji zahtevajo sistematično nego, da bi zagotavljali zanesljivo delovanje...

Ogledaj več