Námorné dieselové motory predstavujú základ komerčnej námornej dopravy, rekreačného plavania a offshore prevádzky po celom svete. Tieto výkonné pohonné systémy vyžadujú prísne postupy údržby, aby sa zabezpečil optimálny výkon, účinnosť spotreby paliva a ...

Zobraziť viac

Námorné plavidlá, ktoré pôsobia v náročných námorných prostrediach, vyžadujú sofistikované systémy motorov, ktoré zabezpečujú spoľahlivý výkon a zároveň udržiavajú prevádzkovú účinnosť. Integrácia pokročilých technológií chladenia priniesla revolúciu v námorných pr...

Zobraziť viac

Námorné pohonné systémy predstavujú jeden z najdôležitejších aspektov výkonu plavidla a priamo ovplyvňujú spotrebu paliva, prevádzkovú účinnosť a životnosť motora. Medzi rôznymi faktormi ovplyvňujúcimi optimalizáciu námorného motora patrí aj vrtuľa...

Zobraziť viac

Námorné dieselové motory sú základom námorných prevádzok a poháňajú všetko – od komerčných rybárskych lodí po luxusné jachty po oceánoch celého sveta. Tieto robustné pohonné jednotky vyžadujú dôkladnú pozornosť a systematickú údržbu, aby sa zabezpečila ich spoľahlivosť...

Zobraziť viacPrevádzkované v najnáročnejších prostrediach sveta, námorné motory sú neustále vystavené morskej vode, vlhkosti a extrémnym kolísaniam teploty, ktoré môžu rýchlo poškodiť konvenčné strojné zariadenia. Prísne námorné prostredie predstavuje jedinečné...

Zobraziť viac

Stavebný priemysel stojí pred kľúčovým zlomom, keď tradičná dieselová technika čelí narastajúcemu tlaku zo strany nových elektrických alternatív. Táto transformácia je obzvlášť zrejmá v oblasti motorov bagrov, kde desaťročia...

Zobraziť viac

Keď dôjde k výpadku bagra kvôli problémom s motorom, musia prevádzkovatelia urobiť kritické rozhodnutie medzi pokusom o samonapravu alebo vyhľadaním profesionálnej služby. Táto voľba výrazne ovplyvňuje prevádzkové náklady, časové plány projektov a životnosť zariadenia...

Zobraziť viac

Prevádzkovatelia ťažkej techniky a správcovia flotily vedia, že udržiavanie optimálneho výkonu motora bagra je kľúčové pre úspech projektu a prevádzkovú efektívnosť. Ak motor bagra vykazuje problémy, môže to viesť k nákladnej prestávke, oneskoreniam...

Zobraziť viac

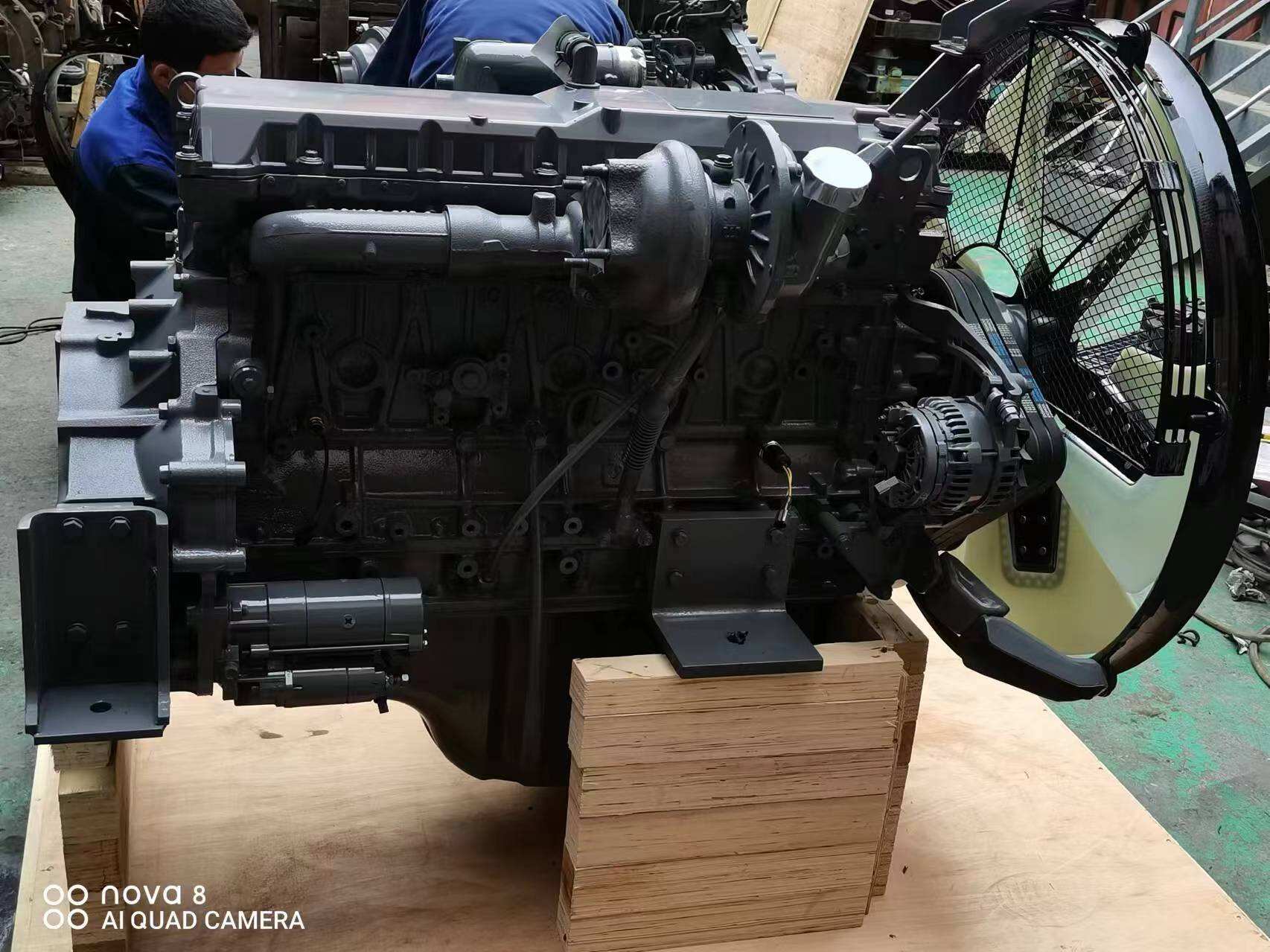

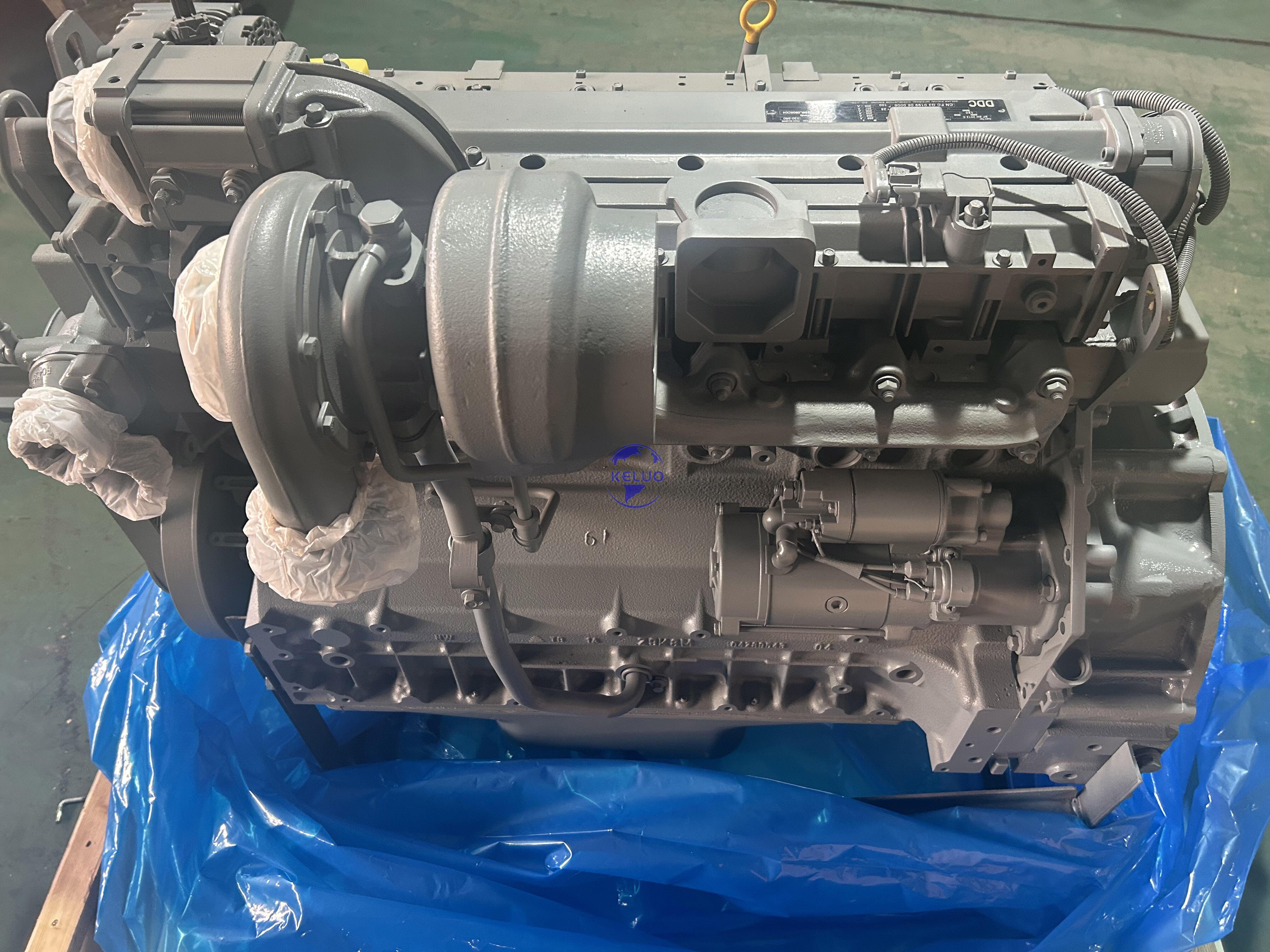

Správna údržba priemyselných motorov je základom zabezpečenia optimálneho výkonu, dlhovekosti a hospodárnej prevádzky vo viacerých aplikáciách. Dobre udržiavaná zostava dieselového motora môže poskytovať desaťročia spoľahlivej služby, ak je podrobovaná pravidelnej údržbe...

Zobraziť viac

Priemyselný sektor strojov sa neustále rýchlo vyvíja, pričom systémy zostáv dieselových motorov sa stávajú čoraz sofistikovanejšími a efektívnejšími. Keď sa blížime k roku 2026, výrobcovia vyžadujú spoľahlivejšie, palivovo úspornejšie a ekologickejšie...

Zobraziť viac

Keď ťažká stavebná technika zlyhá na stavbe, každá minúta výpadku sa prejaví strátou produktivity a príjmov. Motory Caterpillar poháňajú milióny bagríkov, buldozérov a inej ťažkej techniky po celom svete, čo robí spoľahlivé riešenie porúch kľúčovým faktorom bezproblémového prevádzkovania.

Zobraziť viac

Správna údržba motora caterpillar je nevyhnutná na maximalizáciu výkonu zariadenia, zníženie výpadkov a predĺženie prevádzkovej životnosti. Prevádzkovatelia ťažkej techniky a odborníci zo stavebného priemyslu sa spoliehajú na tieto robustné pohonné jednotky, ktoré zabezpečujú spoľahlivý výkon.

Zobraziť viac