Essential Practices for Maximizing Heavy Equipment Performance

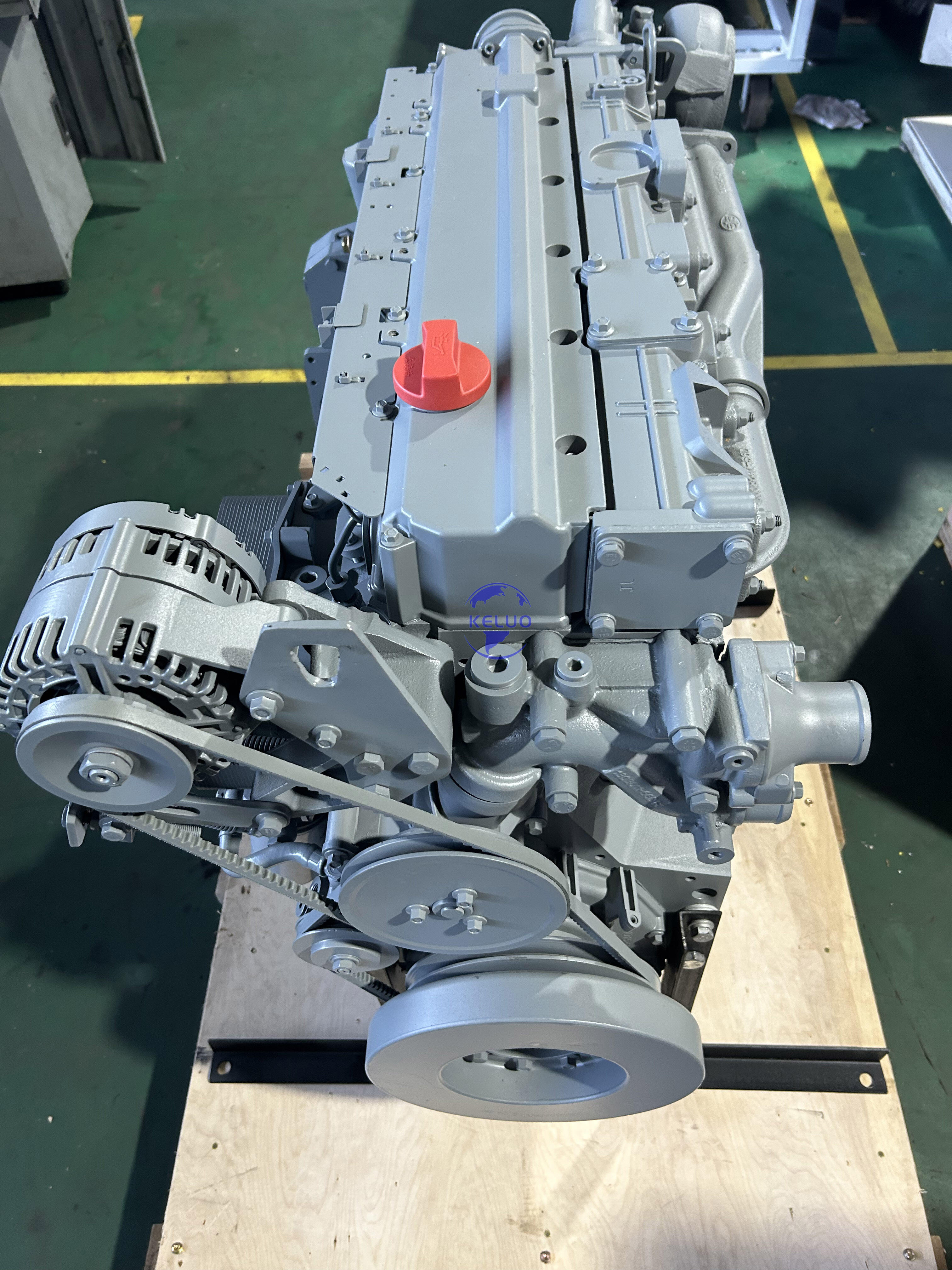

The heart of any construction equipment lies in its powerhouse - the excavator engine. Proper maintenance of this crucial component not only ensures optimal performance but also significantly extends the machine's lifespan while reducing costly downtime. Understanding how to properly care for your excavator engine can make the difference between a profitable operation and expensive repairs.

Construction professionals worldwide recognize that preventive maintenance is far more cost-effective than reactive repairs. When it comes to heavy machinery, especially excavators, the engine requires particular attention due to the demanding nature of construction work. Let's explore the most effective strategies for maintaining your excavator engine and keeping your equipment running at peak efficiency.

Professional Maintenance Fundamentals

Regular Fluid Monitoring and Management

The lifeblood of any excavator engine is its fluids. Engine oil, coolant, and hydraulic fluid levels must be checked daily before operation. Low or contaminated fluids can cause severe damage to engine components, leading to premature wear and potential failure. Professional operators always maintain a log of fluid checks and changes.

Quality engine oil is particularly crucial for maintaining optimal performance. The oil should be changed according to the manufacturer's specifications, typically every 250-500 operating hours, depending on working conditions. Using the wrong type or delaying oil changes can result in increased friction, heat generation, and eventual engine damage.

Air Filtration System Care

Construction sites are notoriously dusty environments, making the air filtration system a critical component of excavator engine maintenance. A clean air filter prevents abrasive particles from entering the engine, where they could cause internal damage. Regular inspection and replacement of air filters should be part of your maintenance routine.

Modern excavator engines often feature dual-stage air filtration systems. Both primary and secondary filters need regular attention. Many machines are equipped with air filter restriction indicators that signal when replacement is necessary. Don't wait for visible signs of contamination - proactive replacement ensures continuous protection.

Advanced Performance Optimization

Cooling System Maintenance

The cooling system plays a vital role in excavator engine performance, especially during extended operations. Regular inspection of radiator cores, cooling fins, and fan belts helps prevent overheating issues. Accumulated dirt and debris should be carefully removed to maintain proper airflow and heat dissipation.

Coolant quality and concentration must be maintained at optimal levels. The correct mixture of coolant and water provides both freeze protection and proper heat transfer characteristics. Experts recommend testing coolant concentration at least quarterly and performing complete system flushes according to manufacturer guidelines.

Fuel System Excellence

Modern excavator engine systems are highly sensitive to fuel quality. Using clean, high-quality fuel and regularly replacing fuel filters helps prevent injection system problems. Water separators should be drained daily, and fuel tanks should be kept as full as possible to minimize condensation.

Proper fuel storage and handling procedures are equally important. Bulk fuel tanks should be regularly tested for contamination and water content. Installing and maintaining high-quality fuel filtration systems at your storage facility provides an additional layer of protection for your excavator engine.

Electronic Systems and Diagnostics

Modern Monitoring Technologies

Today's excavator engines come equipped with sophisticated electronic monitoring systems. These systems provide real-time data about engine performance, including temperature, pressure, and efficiency metrics. Regular diagnostic checks using manufacturer-specific software can identify potential issues before they become major problems.

Telematics systems have revolutionized excavator engine maintenance by enabling remote monitoring and predictive maintenance scheduling. These systems can track engine hours, fuel consumption, and performance parameters, allowing maintenance teams to optimize service intervals and predict potential failures.

Electrical System Integrity

The electrical system supporting the excavator engine requires regular attention. Battery connections should be clean and tight, with terminals protected from corrosion. Wiring harnesses need inspection for wear or damage, particularly in areas subject to movement or exposure to elements.

Starting systems should be tested regularly, as cold-weather operation can be particularly demanding on excavator engines. Alternator output and belt condition should be verified during routine maintenance to ensure reliable electrical system performance.

Frequently Asked Questions

How often should I change the oil in my excavator engine?

Oil change intervals typically range from 250 to 500 operating hours, depending on your specific model and working conditions. However, severe operating conditions such as extreme temperatures or dusty environments may require more frequent changes. Always consult your manufacturer's maintenance schedule and use oil analysis programs to optimize change intervals.

What are the signs of a failing excavator engine?

Common warning signs include unusual noise, excessive smoke, decreased power output, increased fuel consumption, and abnormal operating temperatures. Regular monitoring of engine parameters and prompt attention to any changes in performance can help prevent major failures.

Can I use alternative fuels in my excavator engine?

While some modern excavator engines are designed to work with alternative fuels, it's crucial to verify compatibility with your specific model. Using unauthorized fuel types can void warranties and cause serious damage. Always consult with your equipment manufacturer before considering alternative fuel options.