rebuild engine factory

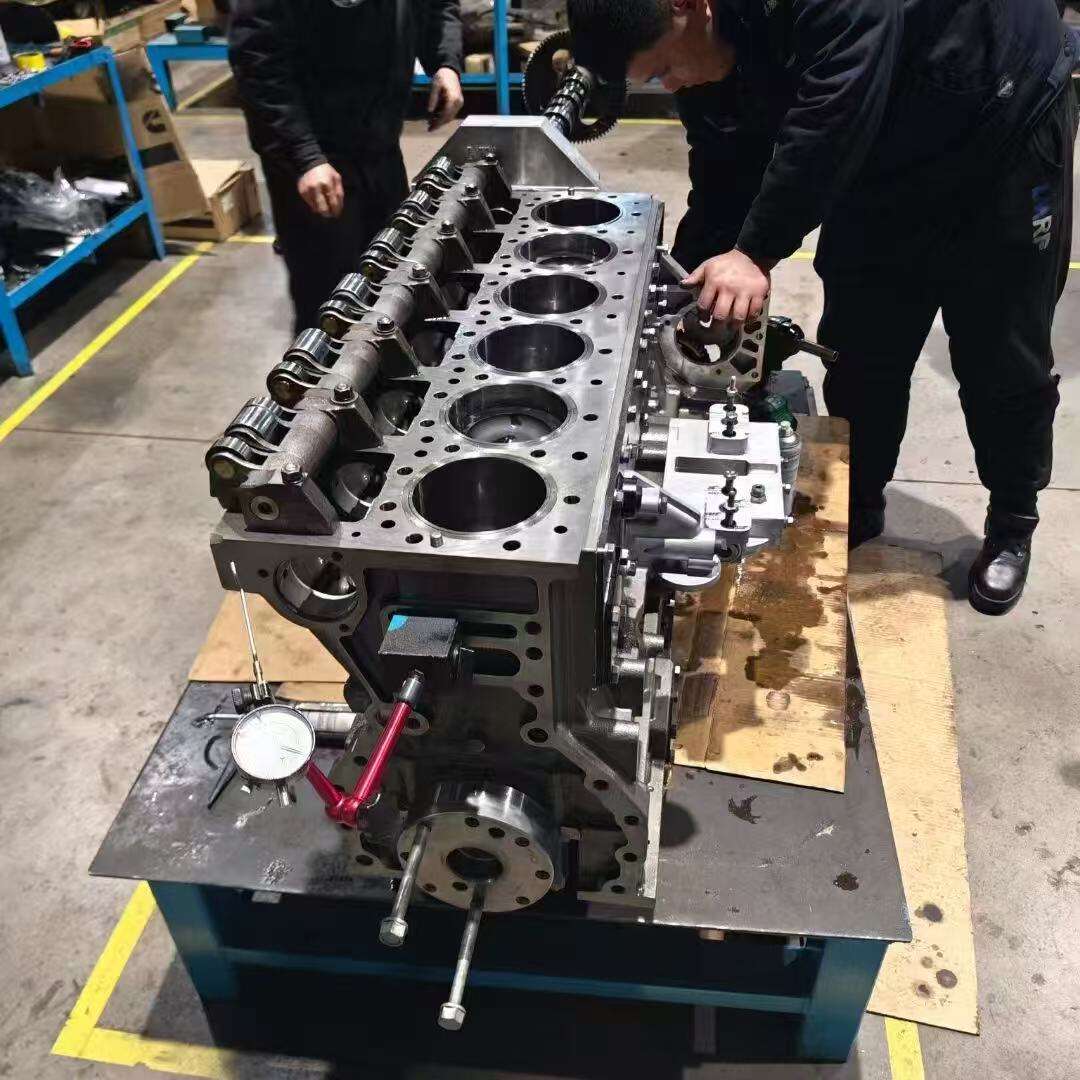

A rebuild engine factory represents a state-of-the-art facility dedicated to the comprehensive restoration and remanufacturing of automotive engines. These specialized facilities combine traditional craftsmanship with cutting-edge technology to breathe new life into worn engines. The factory employs advanced diagnostic equipment, precision machining tools, and sophisticated testing systems to ensure each rebuilt engine meets or exceeds original manufacturer specifications. The process begins with a thorough inspection and disassembly of the core engine, followed by cleaning, machining, and replacement of worn components. Expert technicians utilize computerized measuring instruments to assess wear patterns and determine the exact specifications for replacement parts. The facility houses multiple specialized departments, including cleaning stations, machine shops, assembly areas, and testing chambers. Quality control measures are implemented at every stage, from initial core inspection to final performance testing. The factory maintains an extensive inventory of OEM and high-quality aftermarket parts, enabling quick turnaround times without compromising quality. Modern rebuild engine factories also incorporate environmentally conscious practices, including the recycling of materials and the use of eco-friendly cleaning solutions. This combination of technical expertise, advanced equipment, and systematic quality control makes these facilities essential to both the automotive industry and environmental sustainability.